A wire stripping and crimping machine with error control helps businesses work faster and safer every day. The intended use is to cut wires carefully. It is easy to take off the outside shell. It crimpes the terminal to the right pressure with consistent accuracy. Everything seems to be going as planned. The smart error control system checks every little thing twice. On purpose, it follows the path of the wire. If it finds something wrong, it will turn off the equipment. Because of this, less wire is used.

This is how work time is cut down. This also helps keep costs down every day. Many factories now use the automatic wire stripping and crimping machine all the time. It keeps giving the same results over and over. You might be able to get neatly cut wire ends with its help. It makes employees feel calm and sure of themselves.

Smart Error Control for Zero Waste

Today, wire machines can’t work without error control. There are tiny sensors inside the mechanism. They watch the wire as it moves. They always check the length of the cut. The depth of the strip is carefully checked. They also measure the crimp force while they push. The machine stops right away when it finds a mistake. This quick stop keeps the wire safe. Also, the terminal is safe. This stops you from having to edit the same thing over and over again, which saves you time and effort in the long run.

The error-control wire stripping and crimping machine makes it much easier to cut down on scrap. The final product is of the highest quality. Gentle alerts guide the operator through each step. Clear displays show simple messages. You can fix things quickly and easily by pushing a few simple buttons.

Fast Output with Stable Quality

Speed is very important in wire processing. These devices are known for their quick and steady operation. Wheels that are oiled move easily. Sharp blades stay sharp even after hours of use. The crimp heads always push with the same amount of force. The price of the machine that automatically cuts, strips, and crimps wires seems fair when you see what it can do. You can make more wires in just one hour. The size and shape of all the wires stay the same. This is really helpful for big batch jobs. It is also helpful for custom wire orders. In this case, fast does not mean good.

Easy Use for All Skill Levels

The control panel was designed to be easy to use. You can easily see big icons. Short menus help cut down on setup time. One-touch settings make your daily tasks easier. Anyone, even new employees, can learn the process quickly. The automatic wire strip and crimp machine makes it much easier to cut down on training time. People of all ages can do their jobs better with it. The order of the tasks is very clear. Memory choices can save common tasks. This method may help cut down on repeated setup.

Safe Design for Daily Factory Use

Safety is the main goal of all wire stripping and crimping machines. Gloves that last protect your hands while you work. Finding the emergency stop buttons is easy. Stay safe by staying away from sharp edges. Using the wire machine strip and crimp configuration keeps the work area clean and open. There isn’t much noise when it’s running. Long shifts have very little vibration. Workers may be better at putting quality first. It doesn’t seem tiring to work long hours. Everyday safety and convenience are better.

Wide Wire Range Support

These tools can handle a lot of different kinds of wire. You can use them with PVC wire without any problems. Core cables also work with them. It’s easy to work with medium-gauge wires. It’s easy to change the size settings. The wire strip and crimp machine can handle a wide range of wire sizes because it uses just one system. A wire stripping and crimping machine that can do more than one thing is a good buy. This saves space in the production area. We don’t need as many extra machines as we used to. This helps keep track of the cost of equipment.

Clean Cutting and Perfect Stripping

You can count on clean cuts every time if you use good tools. All of the wires have the same strip length. The inside stays safe and unharmed. The wire cutting, crimping, and stripping tools make results that are clean and accurate. The quality of the electrical contact is better. The life of the product is also longer. The finished wires are neat and look like they were made by a pro. They can be used in finished assemblies. Cutting and stripping accurately makes the end product more valuable.

Low Maintenance and Long Life

You can count on the machine to be strong. The parts inside are resistant to wear. Taking care of someone is easy. The quick checks keep the system running. The machine that automatically strips and crimps wires doesn’t need much upkeep. This will cut down on downtime. It makes manufacturing more reliable. It’s easy to switch out the spare parts. Over time, the cost of upkeep stays low. Because of this, the wire stripping and crimping machine can be used for a long time without breaking down.

Energy Saving and Eco Friendly

One of the main goals of smart motor design is to save energy. When the machine is not in use, it uses less power. Less scrap means less waste. The wire stripping and crimping machine puts protecting the environment first. Manufacturers make less money when they make less energy. It also helps protect the environment. Getting clean production is now much easier. This backs up new ideas for green manufacturing.

Recommended Models from VIMFUN

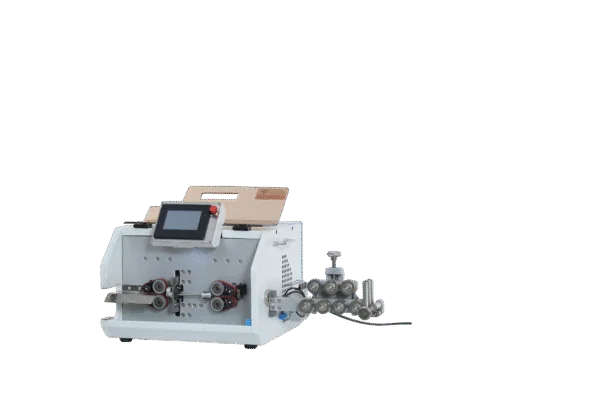

HW-8010 Automatic Wire Stripping Machine for PVC & Core Cables

The design of this model is meant to make work clean and stable. It shreds PVC wire with careful control. It safely handles core cables. The structure is strong and will last a long time. The control system is smart and easy to use. Error checks keep the output stable. It works great for medium and small manufacturing lines. This HW-8010 wire strip and crimp machine is dependable and great for daily use. It makes it possible to produce high-quality goods all the time.

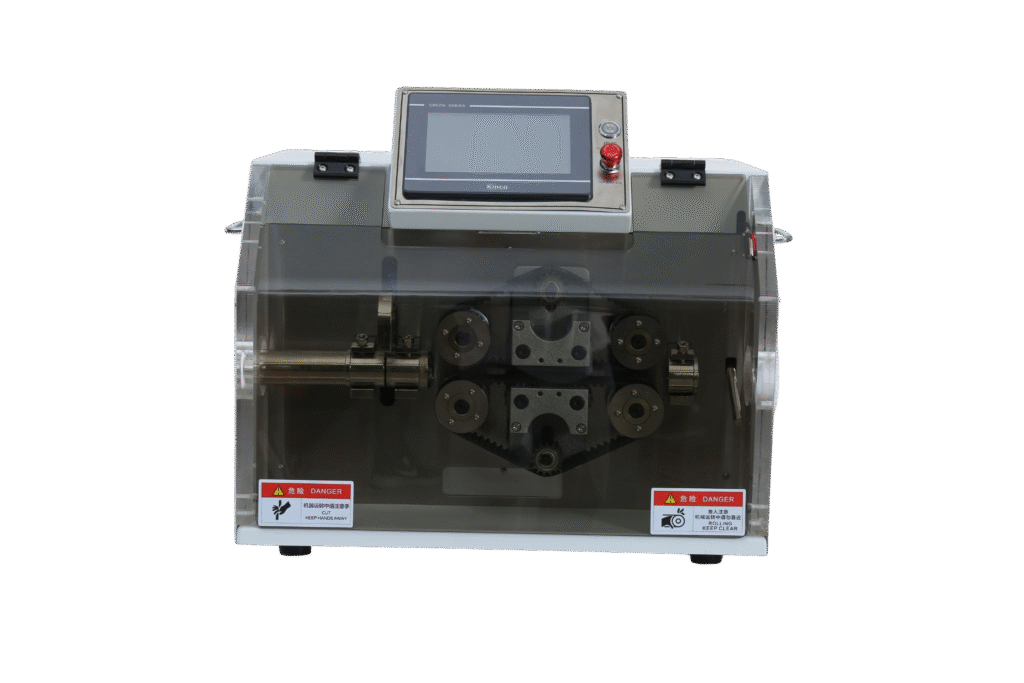

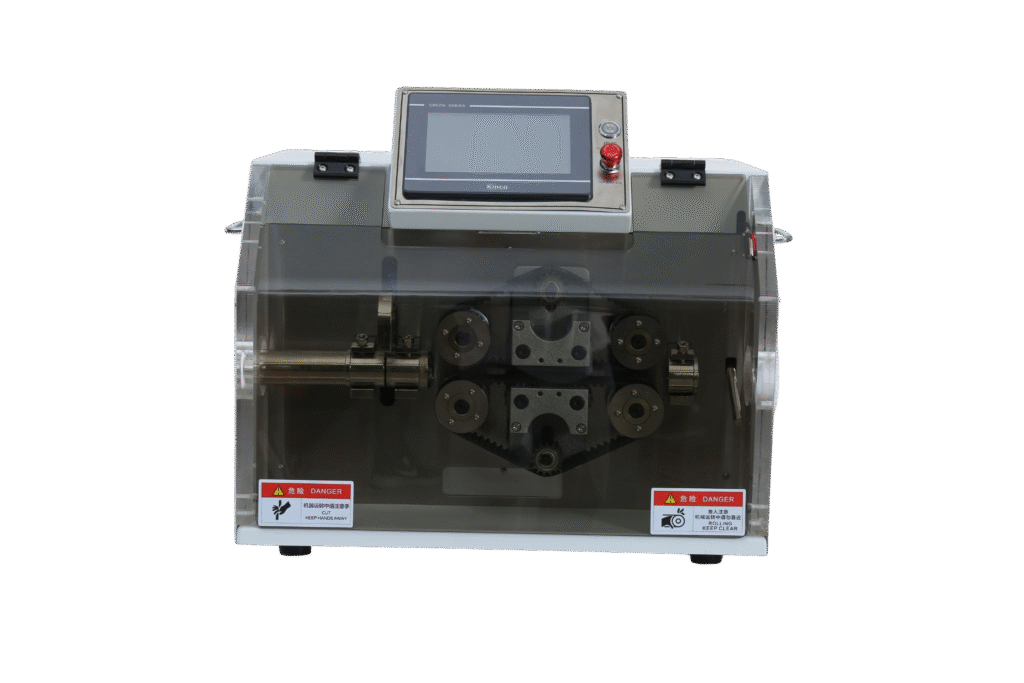

HW-8120 Wire Cutting & Stripping Machine for Medium Gauge Wires

This HW-8120 design works best with thicker wires. It cuts wire very well. It takes off insulation in a neat way. The wire’s shape stays the same after it has been processed. Sensors carefully guide every move. It is great for jobs that require a lot of work. The design of the automatic wire strip and crimp machine guarantees that it will make things that are tough and always the same. It works great in busy, high-demand industrial settings.

HW-B30 Corrugated Tube Cutting Machine for Cable Conduit

This HW-B30 machine is made to cut corrugated tubes. It stops crushing when cutting tubes. Length accuracy is still good. The edge quality is kept neat. It is perfect for getting cable conduit ready. You can use it to make good cable paths. It works great in a wire machine strip and crimp assembly line. In general, the quality of cable management is better.

HW-B30X Automatic Conduit Cutter for Corrugated Sleeves

This HW-B30X cutting tool is the best of the best because it is fast and accurate. There are sleeves of different sizes. We always cut with the same level of accuracy. Fixing mistakes stops cutting the wrong way. So, less material is lost. Because of this, the finish is much better. Adding it to any wire stripping, cutting, and crimping machine system will make it much better. It can be used by modern automated lines.

Key Benefits at a Glance

- Fast wire cutting and stripping

- Smart error control system

- Easy control panel design

- Strong safety protection

- Wide wire size support

- Low waste and clean output

| Feature | Benefit |

| Error Control | Less scrap and fewer mistakes |

| High Speed | Higher output per hour |

| Easy Panel | Faster learning for workers |

| Safety Cover | Better hand protection |

| Multi Wire Support | More job flexibility |

VIMFUN is known for reliable wire processing machines. The brand focuses on strong build quality. It also focuses on easy operation. Their wire stripping and crimping machines fit modern factory needs well. After-sales support is helpful. User guides are clear and simple. Spare parts are easy to get. Visit the official VIMFUN website to explore full product details and support services.

FAQs

- Is this machine good for beginners?

Yes. The interface is simple. Steps are easy to follow. Training time is short.

- Does error control really help?

Yes. It stops errors early. It saves wire and time.

- Can it handle different wire sizes?

Yes. It supports a wide range of wire types and sizes.

- Is the automatic wire cutting stripping and crimping machine price high?

The price matches long-term value. It reduces waste and labor costs.

- Where can I learn more?

You can visit the VIMFUN website for full product information.