A stripping and crimping machine can help people work much more quickly each day. It is intended to cut every wire neatly. It also consistently yields strong, consistent crimps. The finished wire appears neat and is ready for use. The amount of time spent on daily tasks is considerably reduced by these devices. They also help reduce wire waste in all tasks. They are utilized in small shops for routine cable work. Major businesses use them for long, intense production runs.

The work is flawless from start to finish. Many clients now opt to use automated stripping and crimping equipment for better results. The user requires very little effort when using this type of device. It functions using a series of stages and explicit actions.

Automatic Systems Are a Better Choice

Firm hands and total focus are necessary when using manual tools. One small mistake can damage the wire core. This could lead to waste and delays in work. In most cases, automatic machinery eliminates this risk. They follow a set of procedures for each assignment. They are not worn out by long hours. The speed remains constant from sunrise to sunset.

An automated wire cutting stripping and crimping machine completes several tasks in a seamless workflow. First, the wire is cut to size. After that, the lid is carefully taken off. The end is then crimped using powerful force. This results in a smaller workspace. It also lowers labor costs over time. Errors become extremely uncommon. The output becomes more consistent.

Key benefits include:

- Fast output for daily jobs

- Clean strip ends without damage

- Firm and tight crimps every time

- Less hand strain for workers

- Easy use for new staff members

Clean Results for Many Cable Types

Modern machines are designed to accommodate a wide range of cable types. They work well with thin-core wires. They also work well with thick and hard cables. A good automatic wire stripping and crimping machine can quickly change settings. This helps users switch jobs with ease. There is no need for a long setup time. This keeps work moving.

These machines are helpful for many tasks. They are used in power systems. They are used in control panels. They are used in data and signal lines. They are also used in auto harness work. Each wire comes out smooth and clean. Each end fits nicely into the connectors. This improves safety and performance.

Built for Speed and Accuracy

Speed is essential in production work. Accuracy is even more critical for safety and quality. A wire cutting, stripping, and crimping machine offers all three functions in one system. It cuts wires to the exact length each time. It strips insulation without harming the core. It crimps with even pressure for a firm hold.

This balance of speed and accuracy enables companies to maintain high standards of quality. It also helps finish large orders on time. Fewer errors mean less rework. This saves money and effort. The work process becomes smooth and stress-free.

Simple Design That Anyone Can Use

At first glance, these machines may look complex. But they are designed for easy use. Clear control panels guide each step. Buttons are large and simple. Screens show precise numbers and data. Users can see settings at a glance.

A good wire stripping and crimping machine significantly reduces training time. New workers can learn quickly. Daily tasks feel easier and lighter. Work becomes more stable. This helps teams stay productive.

Machine Overview Table

| Feature | Benefit |

| Auto cut | Same wire length every time |

| Auto strip | No damage to wire core |

| Auto crimp | Strong and firm joint |

| Digital control | Easy setup and changes |

| Safety cover | Safe daily operation |

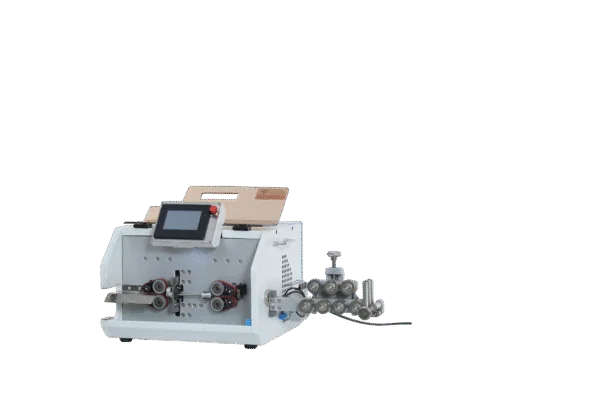

HW-8010 Automatic Wire Stripping Machine for PVC & Core Cables

The HW-8010 is built for daily cable work. It is designed to handle PVC and core cables with ease. The cutting action is smooth and clean. The stripping depth stays exact on each wire. This helps keep wire ends neat. It is a good choice for both small shops and large plants.

This machine works well with an automatic wire strip and crimp machine setup. Together, they help increase output speed. They also help keep results steady. This makes the HW-8010 a trusted tool for regular use.

Best uses:

- PVC cable preparation

- Core wire processing

- Small to medium batch jobs

HW-B Advanced Cable Tubing Cutter with Multi-material Support

The HW-B cutter is designed to work with a wide range of materials. It can cut soft tubes easily. It can also cut rigid tubes without rough edges. The cut ends stay smooth and clean. The tube length stays even for every piece.

This cutter supports complete cable production lines. It works smoothly with any automatic wire stripping and crimping machine system. This makes it worthwhile in many industries.

Key highlights:

- Supports many tube materials

- Fast and smooth blade action

- Clean and even tube edges

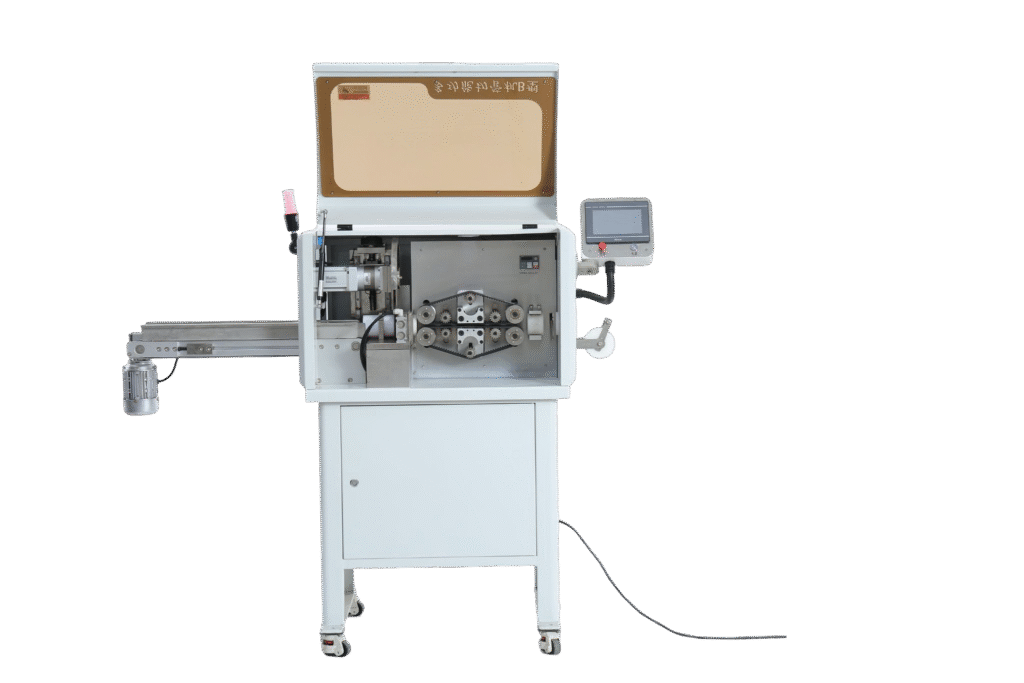

HW-B30 Corrugated Tube Cutting Machine for Cable Conduit

The HW-B30 is designed for use with corrugated tubes in cable protection. It cuts without crushing the tube shape. The round form stays perfect. This helps cables pass through easily later.

This machine integrates seamlessly into automatic production lines. It supports wire cutting stripping and crimping machine work during harness building. The frame is strong. The output stays stable all day.

Why choose it:

- Clean conduit cutting

- Strong and durable body

- Stable and even results

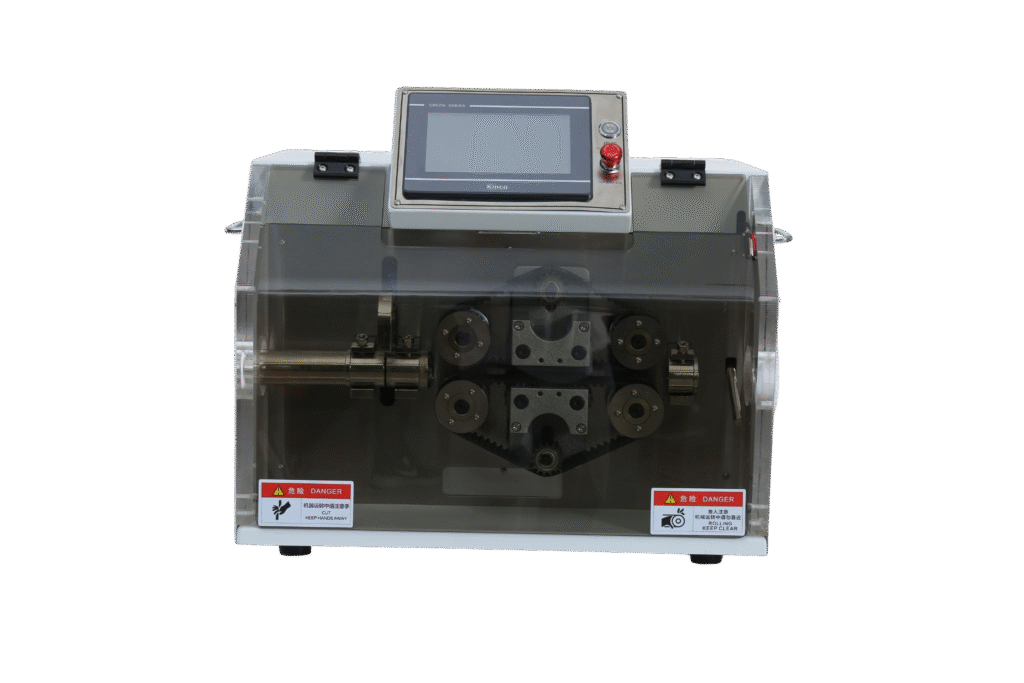

HW-8030HY Heavy-Duty Wire Stripping Machine with Touchscreen

The HW-8030HY is made for heavy work. It handles thick and tough wires with ease. The touchscreen makes setup fast and straightforward. Users can change settings with a light touch. The data is concise and easy to read.

This machine supports high-load production. It works well with an automatic stripping and crimping machine process. It is designed for long-lasting use and durability.

Top features:

- Easy touchscreen control

- Support for heavy wires

- Long life and strong parts

Buy Reliable Stripping and Crimping Machines

For reliable cable machines, visit VIMFUN. The website shows full product details. It also shows clear images and features. Support and service details are easily accessible.

VIMFUN is a wise choice for quality cable tools. It serves small workshops and large factories. The focus stays on quality and trust.

FAQs

- What does an automatic stripping and crimping machine do?

It cuts, strips, and crimps wires independently. It works quickly and consistently delivers clean, even results.

- Can one machine handle many wire sizes?

Yes. Most machines allow easy size adjustment. This helps handle many wire types.

- Is training needed to use these machines?

Very little training is needed. Controls are simple and easy to understand.

- Are these machines safe to use?

Yes. Safety covers and stop features protect users during work.

- Why choose automatic machines over manual tools?

They save time and effort. They reduce errors. They improve overall work quality.