Cable preparation is a fundamental process in electrical and electronic manufacturing. To achieve proper connections, wires must be stripped of their insulation accurately and efficiently. The choice often comes down to a manual wire stripper or an automatic wire stripping machine. While both serve the same purpose, their effectiveness differs greatly depending on the scale and demands of production. This article examines the differences between the two, helping manufacturers identify the best solution for industrial use.

Manual Wire Strippers: Advantages and Limitations

A manual wire stripper is a simple hand tool designed for removing insulation from wires. It is inexpensive, portable, and suitable for small-scale tasks or repair work. However, manual stripping is labor-intensive, requires skilled operators, and often leads to inconsistent results. In large-scale cable harness production, manual strippers cannot keep up with the speed and accuracy required by modern industries.

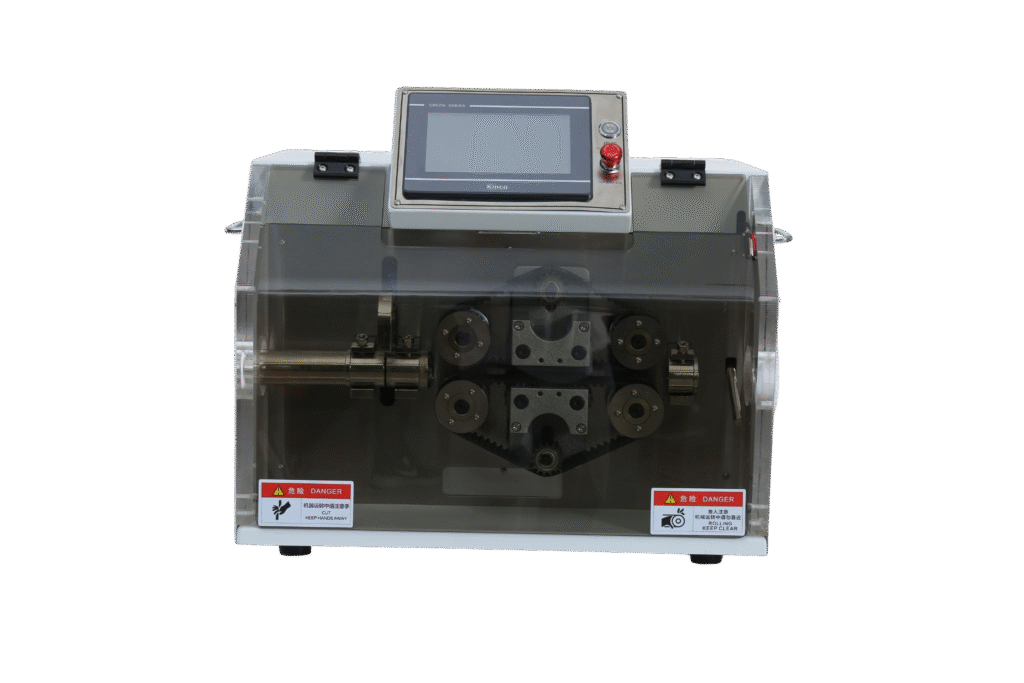

Automatic Wire Stripping Machines: Precision and Productivity

An automatic wire stripping machine, on the other hand, is designed for mass production and industrial applications. These machines offer programmable settings that adapt to different wire sizes and insulation materials. Their ability to deliver precise, repeatable results makes them invaluable in industries such as automotive, aerospace, and electronics manufacturing. Compared to manual strippers, they dramatically reduce labor costs and processing time.

Cost Efficiency Over Time

Although the initial investment in an automatic wire stripping machine is higher than purchasing manual tools, the long-term benefits outweigh the cost. With the ability to process thousands of wires per day, these machines improve throughput and reduce error-related waste. Over time, the savings in labor and material loss make automation the more cost-effective option.

Industrial Applications and Use Cases

- Automotive industry: Wire stripping machines ensure reliable wiring harnesses for vehicles.

- Electronics manufacturing: They allow precise processing of delicate wires in high-density circuits.

- Aerospace: Safety-critical wiring systems benefit from the accuracy of automated stripping.

- Household appliances: Large-scale production requires consistency and speed, both delivered by automated solutions.

Comparison Summary

- Manual wire stripper: Low cost, portable, but labor-intensive and inconsistent.

- Automatic wire stripping machine: Higher investment, but superior in precision, speed, and long-term efficiency.

Conclusion

When evaluating wire stripper vs wire stripping machine, the choice depends on production needs. For small workshops or occasional use, manual strippers may be sufficient. However, for industrial-scale operations, automatic machines provide unmatched efficiency, consistency, and cost-effectiveness.

👉 Explore our range of automatic wire stripping machines today and find the ideal solution for your industrial cable processing needs.