Wire Harness Manufacturing

Wire harness manufacturing plays a pivotal role in the automotive and electronics industries, where precision and reliability are non-negotiable. As vehicles evolve with advanced electronics and consumer devices demand compact, high-performance wiring, standardized solutions often fall short. Customization in wire harness manufacturing has become essential to address the unique requirements of these sectors, from complex automotive systems to intricate electronic assemblies. Partnering with Hewang Automation Equipment Co., Ltd., VIMFUN delivers tailored manufacturing processes that enhance performance, safety, and efficiency, underscoring the importance of differentiation in these dynamic industries.

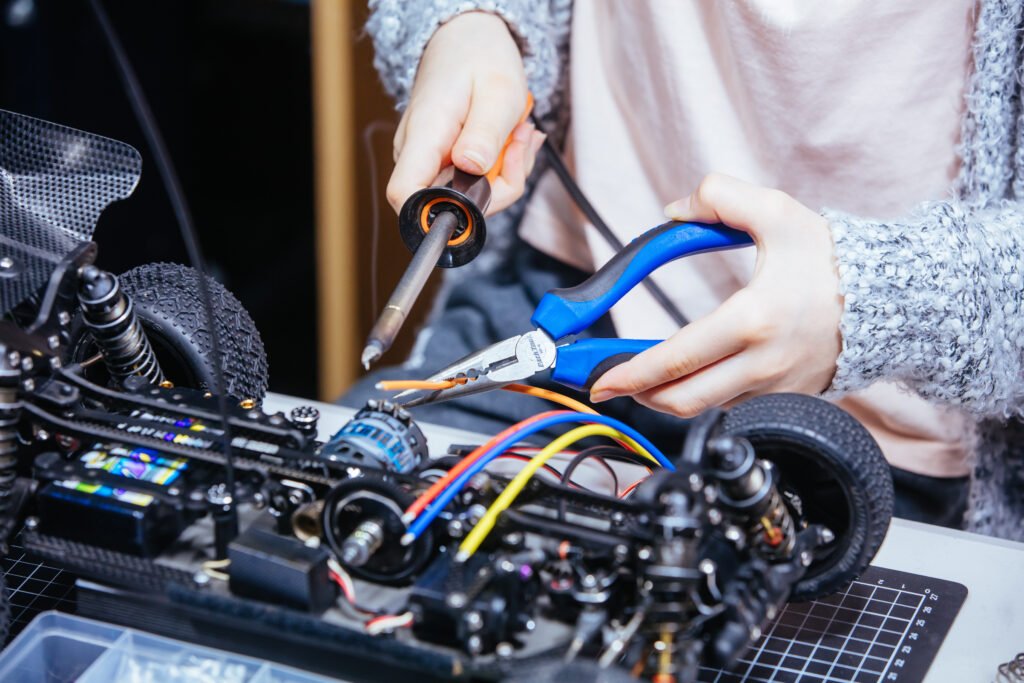

Technical Features and Process

Wire harness manufacturing by VIMFUN incorporates advanced technologies to meet diverse industry needs. The process supports a range of wire sizes, from 0.5 mm² for electronics to 500 mm² for automotive power cables, with stripping and crimping tolerances of ≤0.002*L. Key features include rotary blade stripping for multi-layer cables, mid-stripping up to 32 segments, and customizable crimping for various terminal types (e.g., MIL-spec, ferrule). The workflow integrates 7-inch Kinco touchscreens, servo motors, and MES systems for real-time monitoring, using components like Taiwan ball screws and AirTAC valves. This ensures precision in handling coaxial cables, flat cables, and double-sheath designs, tailored to specific industry specifications.

Comparison with Traditional Methods

Traditional wire harness manufacturing, often relying on manual assembly and generic tooling, struggles to match the precision and speed of customized automated systems. Manual processes typically produce 20-50 harnesses per hour with inconsistent quality, limited by human error and the inability to adapt to diverse wire types. In contrast, VIMFUN’s automated systems, such as the HW-8030, can achieve 1,000 harnesses per hour with uniform results. Conventional methods also require extensive rework due to mismatched designs, while customized automation reduces setup time by up to 70% and ensures compliance with stringent standards like ISO9001 and CE, offering a clear edge in efficiency and quality.

Industry Application Scenarios and Differentiation

Customization in wire harness manufacturing is critical due to the distinct needs of automotive and electronics industries. In automotive applications, the HW-8500 supports high-voltage cables up to 500 mm² for electric vehicle battery systems, requiring robust crimping and labeling for safety. The HW-8030Z, with its mid-stripping capability, addresses the complex wiring harnesses of advanced driver-assistance systems (ADAS). In electronics, the HW-2T crimping machine handles fine-gauge wires for compact devices like smartphones, while the HW-8T accommodates multi-pin connectors for IoT gadgets. This differentiation ensures optimal performance, from heavy-duty automotive harnesses to delicate electronic circuits.

Customization Value in Automotive and Electronics

The value of customization lies in its ability to address industry-specific challenges. For automotive manufacturing, customized wire harnesses integrate features like sequential crimping and hot stamp marking to meet durability and traceability needs under harsh conditions. In electronics, the focus shifts to miniaturization and precision, with tailored stripping lengths and mold designs for multi-conductor cables. VIMFUN’s collaboration with Hewang’s 10,000-square-meter facility enables rapid prototyping and scalable production, allowing for unique configurations such as robotic arm integration (HW-8030HYJ) or MES-driven automation. This adaptability ensures that each harness aligns with the exact performance and safety requirements of its application.

Case Studies and Future Trends

A recent case study highlighted a partnership with an automotive OEM, where the HW-8500 was customized for a new EV model, incorporating high-voltage crimping and labeling, resulting in a 30% efficiency gain. In electronics, a smartphone manufacturer utilized the HW-2T for ultra-fine wire harnesses, reducing failure rates by 15%. Future trends point toward Industry 4.0, with VIMFUN exploring IoT-enabled manufacturing and AI-optimized designs. These advancements promise greater customization, enabling real-time adjustments and predictive maintenance to meet the evolving demands of automotive and electronics sectors.

Conclusion

Customization in wire harness manufacturing is a game-changer for automotive and electronics industries, offering tailored solutions that outperform traditional methods. Its ability to address differentiated industry needs, supported by advanced technology and innovation, delivers unmatched value. To explore how customized wire harness manufacturing can benefit your operations, click to view our wire harness solutions for more details.