A computerized wire-cutting and stripping machine makes everyday cable work easier and faster. With its help, teams can finish more work in less time. The machine cuts wires quickly and cleanly. It cuts insulation quickly and cleanly. Workers don’t have to work as hard or as much. This automatic wire cutting and stripping machine, which is controlled by a computer, keeps up a steady output all day long. The length stays the same. The width of each strip stays the same. It works for both big businesses and small workshops. It can help anyone, from beginners to experts. The workflow gets better with each shift.

Important Uses of High-Speed Digital Machines

A faster pace always leads to more production. When machines run faster, they make more things. Cutting wire neatly and accurately cuts down on waste. Less waste means more savings. Digital systems help keep people from making mistakes. They keep each cut the same. A modern wire cut and strip machine makes sure that the wire is always the right length and size. Because of this accuracy, less work needs to be done again. Time and money are saved. Workers are less stressed. Teams can easily reach their daily goals if they are less stressed. This makes it easier for managers to plan. Customers are also happy.

Key Benefits of Digital Wire Cutting Systems

- Cutting at a steady and quick speed

- Every wire has a strip that is the right length.

- Simple digital display with clear numbers

- Endurance work with little noise in the background

- Less vibration means that things run more smoothly.

- Fits a lot of different sizes and types of wire

Modern assembly lines should use automatic wire cutting and stripping machine for these and other reasons. It meets the needs of a growing business.

Applications Across Industries

The wire stripping and cutting machine is used a lot in a lot of different fields. It helps with production every day in:

- Plants that put together electronics and printed circuit boards

- Lines for wiring and cable assemblies for vehicles

- Companies that make appliances and tools for the home

- Strong solar cable setups

- Stores for switchboards and control panels

It also works with full production lines that have an automatic wire cutting, stripping, and crimping machine to speed up and make output more consistent.

Advanced Features That Improve Daily Work

Digital control panels make it easy for users to set the right wire length. LCD panels show numbers in a simple way. Functionalities that save information in memory make it possible to keep doing the same tasks over and over. It makes setting up faster. It also helps keep mistakes from happening. These tools make the automatic wire cut and strip machine work better. Output stays the same from dawn to dusk. Quality stays high even during long runs. The operators feel more sure of themselves. The training sessions don’t last long.

Strong Build for Long Use

Parts made of metal last longer and are stronger. The machine stays steady even when you work quickly because it is well-built. The parts are strong and fit well. Because of how it was made, it needs less maintenance. Even a used wire cutting and stripping machine can last longer if strong parts are used. A longer life means lower costs overall. For manufacturers, it’s a good investment for the future.

Energy-Saving Design

Use motors that save energy to cut down on how much electricity you use. You will spend less on utilities each month if you save energy. This is very important for factories with a lot of machines. Over time, the savings become clear. This is extremely important when assessing the wire cutting and stripping machine price and value over time. Saving energy is good for the environment.

High-Speed Machines from VIMFUN

HW-8030HYJ Multi-core Cable Stripping Machine with High Accuracy

The main job of the HW-8030HYJ machine is to manage several core cables. It easily handles complicated wires. Extraction stays the same and smooth. Cutting is still accurate and neat. The machine always does the job perfectly.

- Clean results from sensors with high accuracy

- Consistent feeding mechanism for easy movement

- Good for wires with many cores and complex shapes

It works well for assembly lines that need to strike a careful balance between speed and automatic wire cutting and stripping machine price.

HW-B Advanced Cable Tubing Cutter with Multi-material Support

The HW-B Advanced Cable Tubing Cutter works well with many different kinds of tube materials. It can hold tubes that are both flexible and stiff. The cutting edges stay neat and clean.

- Finishing edges perfectly and easily

- A lot of production because of the fast cutting speed

- Simple changes for quick setup

It works well with a wire cutting, stripping, and crimping machine in full cable processing lines.

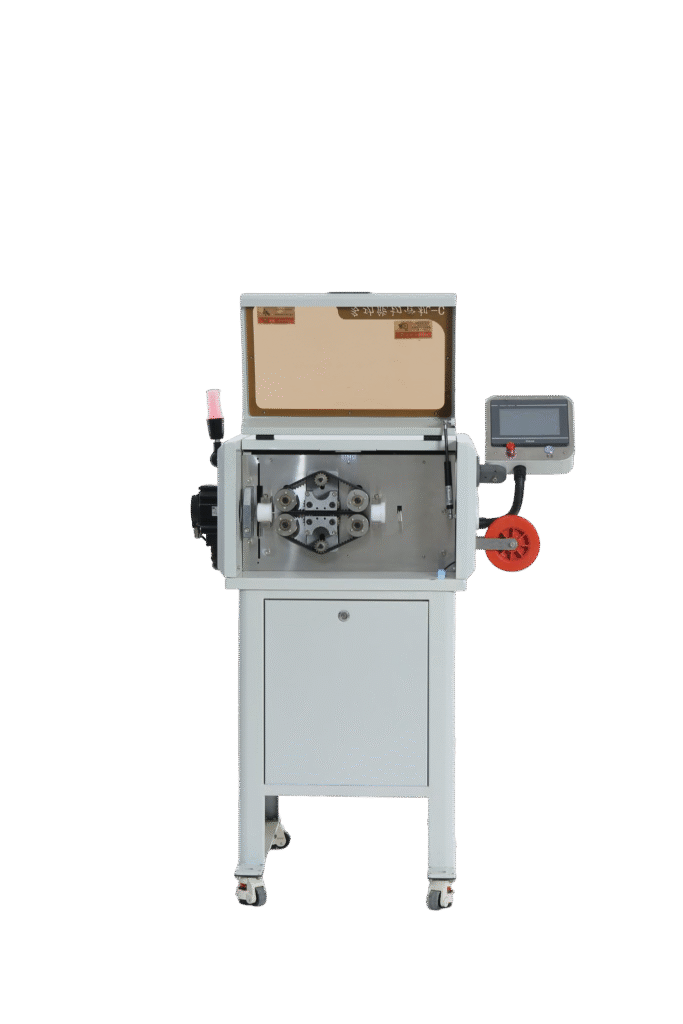

HW-C High-Precision Tube Cutting Machine for Braided Sleeves

This HW-C Machine is good at making braided sleeves and covers. It won’t hurt to cut it; it won’t pull or tear. Cutting keeps the edges sharp.

- After cutting, the ends won’t fray.

- Making sure the blade moves safely and smoothly

- Length calculations that are accurate and dependable

This is a big help for any wire cutting and stripping machine China solution, whether it is used for export or for use in China.

VM-D07 SC-D10 Semi-automatic Coax Cable Stripper Stripping Machine

This VM-D07 SC-D10 Semi-automatic type is meant for coax cable work. It takes off layers slowly. Accurate control of depth is kept.

Digital Wire Cutting Solutions

| Feature | Digital High-Speed Machine |

| Speed | Very fast and stable output |

| Accuracy | High digital control system |

| Waste | Very low material loss |

| Operation | Easy, safe, and user friendly |

| Use Case | Mass production and small batch |

Buying Tips for Digital Wire Cutting Machines

- Check the supported wire size range

- Confirm the required cutting speed

- Compare service and spare support

- Review the full wire cutting and stripping machine price

- Plan for future production upgrades

These tips help buyers choose the right automatic wire cutting stripping and crimping machine with confidence.

VIMFUN provides smart and reliable wire cutting and stripping machine solutions. Each machine is tested before delivery. Designs focus on easy use. Controls are simple. Support teams respond fast. Spare parts are available. Training help is clear and friendly.

FAQs

- What is a digital wire cutting and stripping machine?

It is a machine that cuts and strips wires using digital control. It offers high accuracy, clean results, and fast speed for modern production needs.

- Can a single machine handle multiple wire types?

Yes. Many digital machines support thin, short, and multi-core wires with simple settings.

- Is the machine easy to use?

Yes. Simple screens, clear buttons, and short setup steps make operation easy for users of all ages.

- How to judge the right price?

Buyers should compare features, speed, build quality, and service support with the automatic wire cutting and stripping machine price.

- Where can I buy reliable machines?

You can explore trusted, proven solutions on the VIMFUN website for advanced, reliable wire processing systems.