Programmable Stripping and Crimping Machine are very important to many modern wire companies because they help workers get more done in less time. These smart machines crimp the ends and strip the wire in one smooth motion, so you don’t have to move the wire from one tool to another. These tools could be useful in both small, quiet stores and big, busy factories. Using them can help you save time, avoid making sloppy cuts, and make sure that every wire is neat and tidy.

A lot of people choose to buy an automatic wire stripping and crimping machine for sale because it’s quick and easy to use. New employees don’t have to learn much to use these technologies. Because of this, teams can do more with less stress.

Better Option for Your Daily Work

These Stripping and Crimping Machine tools are used every day in a number of fields, such as wiring cars, fixing household cables, and making electronic devices. They carefully peel off the outer layers of wire, cut it cleanly, and then push the ends of the wire with enough force to keep it taut. Many small businesses are looking for tabletop wire crimping machines because they need an affordable tool that can still produce high-quality results. These modules help new businesses get off to a good start, grow quickly, and provide better customer service. They also help older businesses save time on each wire set.

Stripping and Crimping Machine to Boost Quality

The tools make work better by cutting wires evenly and exactly. They help protect the softer parts of the wire from damage and keep the wires in good shape for longer. Users can easily change the size, length, pull force, and crimp force in just a few steps. Stores can make sure that each line always looks clean and professional by using these parameters. People often ask how to calibrate a wire crimping machine, and it’s not hard to do. Pick the right wire size, test one wire, and then change the pressure to get the best crimp. When the tool is set up correctly, it always gives the same clean result.

Best Use for Coax and Core Cables

Some stores sell coax cable and multi-layer lines, which are both fragile materials. These stores are looking for the best coaxial cable stripping and crimping machine because coaxial lines need to be stripped slowly, carefully, and gently. These units are in charge of safely removing the layers. They are used by TV stores, home network stores, audio shops, and video tech teams. You can make ends that are clean, fit well, and send clear signals with these tools. They promise that the cable will stay stable, strong, and safe for a long time.

Strong Tools for Auto Wire Shops

Huge factories that make dozens of car wire harness sets every day need strong machines that can work for hours without stopping. The industrial wire processing machine for automotive harness is perfect for this kind of work that takes a lot of time and effort. It strips wires quickly, crimps them with force, and works with wires of different sizes very well. These machines cut the wire correctly the first time, which cuts down on waste. They keep the quality of each pair of wires high, speed up the process, and let you work long hours.

Clear Price and Low Cost Models

Some companies still want a powerful tool even if they don’t have much money. They look up the price of a semi-automatic terminal crimping machine so they can save up enough money and choose the right model. Some tasks on these semi-automatic devices are done by hand, while others are done automatically. Thanks to this, stores can now get cleaner results without spending a lot of money on whole vehicle systems. These tools will be helpful for shops that want to grow steadily at a reasonable cost.

Tools for Multi-Core Cables

Shops often deal with thick, multi-core wires that are hard to strip by hand. They want a good multi-core cable stripping and crimping machine that can cleanly take off the outer shell and peel each core without hurting it. These devices keep each core safe and polished. Because one machine can do many things, they help stores save time. Because the tool is doing the harder tasks, workers can focus on other, more advanced tasks.

Air vs Power Units

A common question from buyers is what the difference is between a pneumatic and an electric wire crimping machine. Pneumatic units are great for big jobs with a lot of work to do every day because they use air pumps that make a lot of force. Electric devices are quieter, easier, and cleaner when they are always getting power. They really shine in smaller places or inside buildings. Both types of cleaners work well. The best choice depends on the size of the store, how many people go there every day, and how much noise is needed.

Clean Care for Long Life

If you take good care of each instrument, it will last a long time and work well. Shops use a wire crimping machine maintenance checklist to make sure everything is safe. Cleaning off the dust, checking the blade, running crimp tests, oiling the moving parts, and making sure the wires fit tightly are all things that are often on such a list. If you take good care of the equipment, it will last longer and need fewer repairs.

Best Stripping and Crimping Machines

- HW-8010 Automatic Wire Stripping Machine for PVC & Core Cables

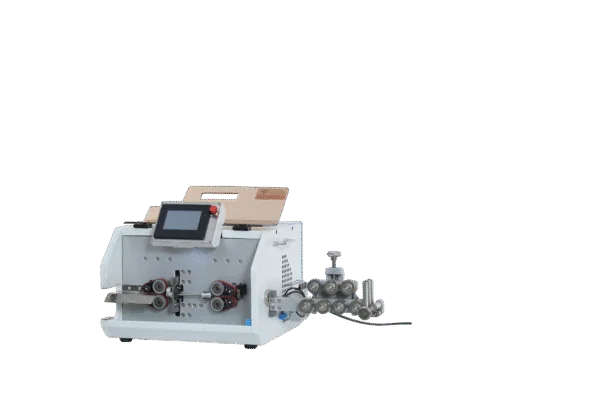

If your business works with PVC cables and is medium-sized, the HW-8010 is a great choice. It cuts wires cleanly and moves smoothly while stripping them. It keeps a steady amount of pressure on the core cables. It can fit into tight spaces easily because it is small and light. Even people who have never used them before will be able to figure them out quickly. It’s a good choice for stores that want to work quickly and without stress.

- HW-8030HY Heavy-Duty Wire Stripping Machine with Touchscreen

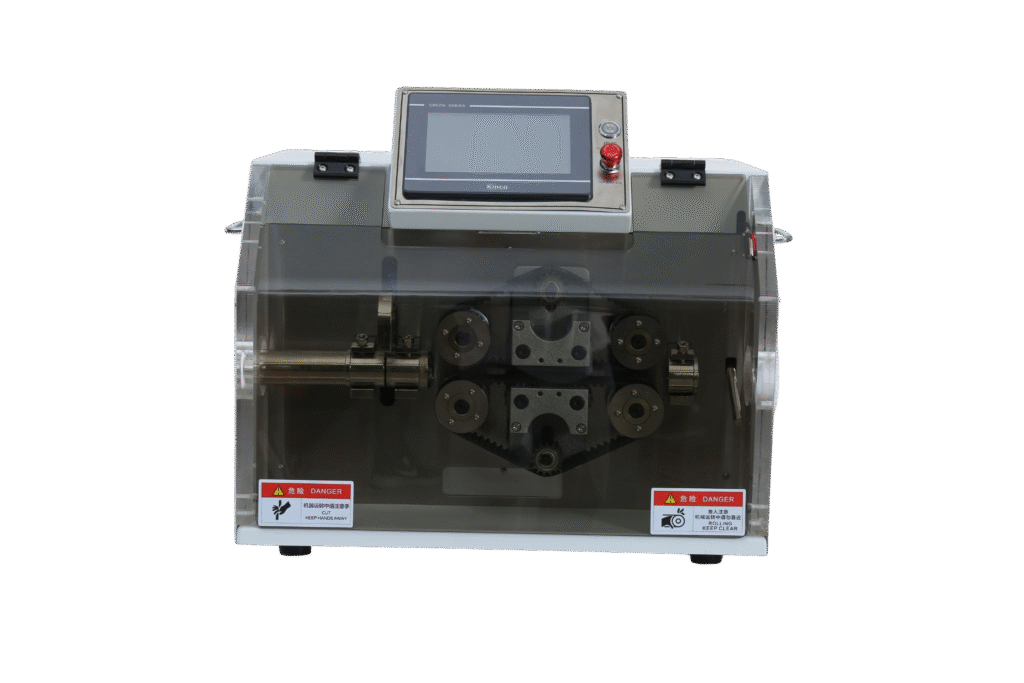

The HW-8030HY can handle hard work and thick wires. The device’s clear touchscreen makes it easy and quick for the user to change the wire size. It keeps going and going. It protects cables and gives off a lot of power while making clean cuts. It’s a good choice for big buildings that do a lot of work.

- HW-8240 High-Speed Cable Stripper for Industrial Use

The HW-8240 is made to work quickly. It neatly strips each end at the rate of many wires per hour. Big cable plants use this technology to make their daily tasks go faster. The parts are strong and will last a long time. It keeps every cut clean so that wire setups work better.

- HW-B30X Automatic Conduit Cutter for Corrugated Sleeves

The HW-B30X fits perfectly with tough corrugated sleeves. All of the sleeves are cut evenly and cleanly. Shops that work with sleeve lines a lot will like how it fits a lot of different sleeve sizes. It is simple, reliable, and strong.

Key Points to Check in Stripping and Crimping Machine

- Clean and even cut

- Fast strip time

- Easy crimp fit

- Low noise

- Strong body build

- Simple settings

Good Uses of Stripping and Crimping Machine

- Auto wire shops

- Home cable repair

- Net cable shops

- Audio shops

- Train wire work

- Device build shops

Stripping and Crimping Machine Types

| Type | Use | Size |

| Small Bench Unit | Small shops | Small |

| Mid Speed Unit | Home wire tasks | Mid |

| High Speed Unit | Big plants | Large |

| Sleeve Cutter | Sleeve lines | Mid |

Select VIMFUN for the Better Quality

VIMFUN offers strong cable tools for shops of all sizes. Their products last long, work smooth, and are easy to learn. Their site provides clear information, fast assistance, and secure parts. Many shops trust VIMFUN when they want clean wire work and simple support. They offer the most advanced materials that are best to last for a long time. The control panel of the stripping and crimping machine makes the controlling work very easy.

FAQ

- Are these units hard to use?

No. They are simple to learn.

- Do they need care?

Yes. Daily cleaning helps a lot.

- Can they strip thick wires?

Yes. Many models can.

- Do they save time?

Yes. They cut work hours fast.

- Can small shops use them?

Yes. Small bench units fit tiny rooms.