Smart wire processing machines are used for the wire and tube works. These are used for cutting and stripping the wires smartly. These machines work fastly and easily to produce the same and accurate outcome every time. Many sectors use these machines for vital wire and tube works. Wire processing machines make it easy to have the best results in less time. For secure and the best outcomes these machines are the exact fit for many industries. You can handle the tough projects easily and smartly with the advanced features of wire processing machines.

Multi-functional Tube Cutter

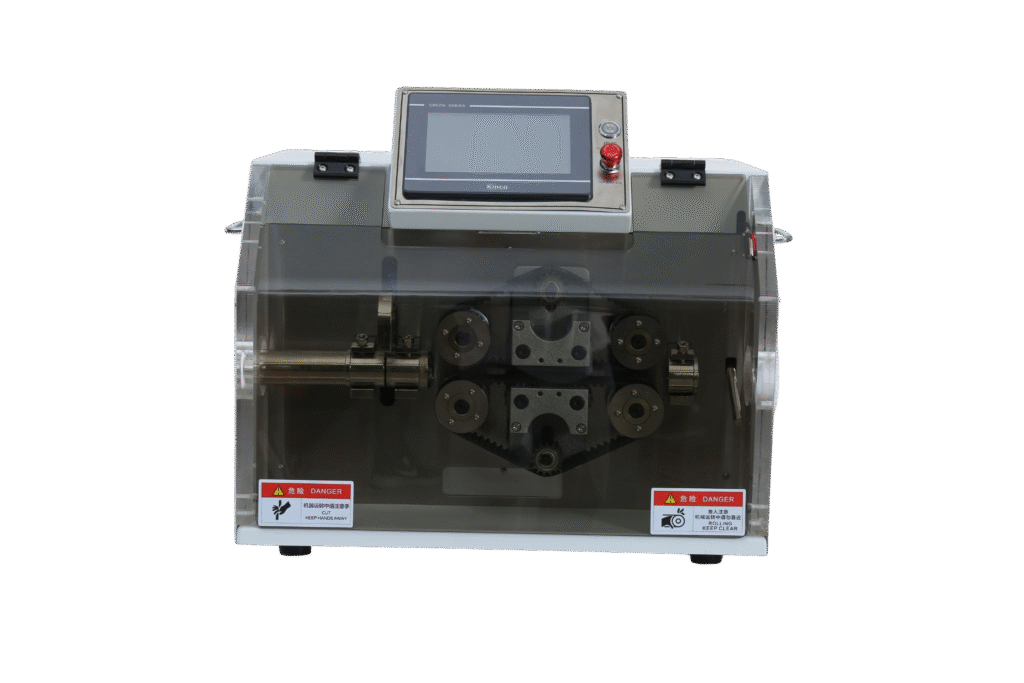

HW-C High-Precision Tube Cutting Machine for Braided Sleeves

This automatic wire cutter machine makes smooth and clean cuts for braided sleeves whenever you use it. It is small, fast, and safe, even for new workers. It saves waste and raises output for your shop. It is easy to move and set up in any space. It makes work simple for new or skilled workers and gives the same daily results. It also has easy blade change, low noise, and steady feed to make each cut exact. People can cut many sleeve thicknesses and keep the same high result with no trouble.

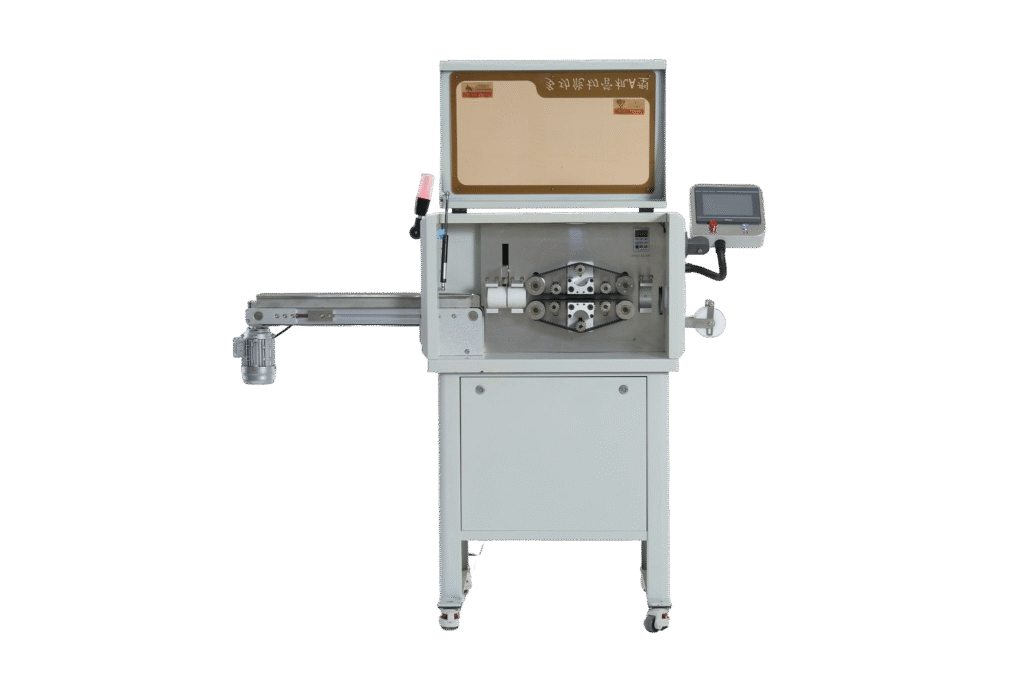

HW-A Multi-functional Tube Cutting Machine

This wire cutting machine works on many tube sizes in one machine. It helps you cut tubes fast with few mistakes and keeps each piece neat. It is excellent for daily factory jobs that need speed. It runs long hours without stopping or overheating. It keeps cuts neat and ready for the next steps in the process. It can work with mixed tube materials, offers fast speed change, and requires little care, so your plant stays running without breaks.

Corrugated Tube Cutter

HW-B60 Large-Diameter Corrugated Tube Cutter

This automatic wire cutting machine cuts large corrugated tubes with ease and clean edges. It is strong and straightforward to set up with clear guides. It keeps tube ends neat for a better fit every time. It cuts heavy tubes fast and clean to save time. It helps workers stay safe with strong clamps and guards. It also holds the tube steady with clamps to stop slipping, and it shows a precise digital readout to check size and cut count for easy tracking.

HW-B30X Automatic Conduit Cutter for Corrugated Sleeves

This wire processing machine cuts small to medium corrugated sleeves without effort. It is light, quick, and steady to use all day. It keeps your workflow smooth with no jams. It can run all day and hold its shape for constant quality. It gives each cut the same size and a clean look to save time on rework. It also has an auto stop if jammed, a quick guide change, and an easy screen to set the length. These extras give more control, safer use, and fewer mistakes.

Computerized Wire Stripping Machines

HW-8240 High-Speed Cable Stripper for Industrial Use

This automatic wire cutting and stripping machine is built for speed and clean work on large jobs. It strips and cuts large batches with no harm to wires. It works well for large plants that need to move fast. It helps teams do more with less effort and fewer errors. It runs quietly and steadily, so workers can focus. It also logs each job, saves settings for later, and links to factory software to track work with reports.

HW-8010 Automatic Wire Stripping Machine for PVC & Core Cables

This strip and crimp machine can easily handle PVC and core cables every shift. It makes clean ends ready for crimp or solder with no burrs. It cuts waste and saves time each day. It keeps wires neat and safe for the next steps in assembly. It also has auto tension adjust, tool-free setup, and smart sensors to watch for real-time mistakes to protect your cables.

Key Applications of Wire Processing Machines

New Energy & EV

- Clean cuts for battery wires every time with steady blades.

- Fast prep for high-voltage cables with few mistakes and no burn.

- Safe work for EV parts without harming staff or parts on the line.

- Easy change between cable sizes for new EV models and updates.

Medical Devices

- Soft tube cutting for medical use with care and no damage to fragile parts.

- Exact wire machines for sensors and small parts with clean edges and no dust.

- Safe and clean results for health gear ready for final use with patients.

- Ability to store sterile parts without risk of dirt or loss.

Automotive Wiring

- High-volume harness work is done fast for all car lines with a neat finish.

- Quick change of wire size with no stop to keep pace with demand.

- Strong, repeatable output for car parts with low defect rates.

- Extended run time without cooling down or slowdowns.

3C-Electronics

- Tiny wire machine tools for small cables and fine work at high speed.

- Low waste on micro parts with neat cuts and no burr for clean boards.

- Fine quality for circuit links that need a steady flow and low error.

- Support for mixed connectors and tiny plugs with easy setup.

Industrial Automation

- Fast cut for control cables with steady work and exact size for robots.

- Stable work 24/7 without breaks or drift for smooth lines.

- Easy link to robots and auto lines with built-in data share.

- Complete reports on cut counts and times for managers to see progress.

Home Appliance Wiring

- Neat harness prep for home devices of all sizes and types.

- Less time to cut and strip wires with simple steps for workers.

- Long-life auto machinery for shops with little care and upkeep.

- Support for many home device wire types with one unit.

Our Smart Working Process

Requirement Confirmation

We will talk with you to learn about your needs and listen to each detail about your wires. After that we carefully check the tube and wire size and plan stock for all parts. We also review safety rules and space limits at your site.

Design & Validation

We plan the wire processing setup with skill and make models for tests. Also we test before mass work to be sure and show proof to you. Then our team adjusts the design based on your feedback until it is right.

Technical Agreement

After that we sign a clear deal with easy words and pictures to guide you and lock all specs and delivery times for trust and record for both sides. We also give training plans so your staff can use the machines well.

Manufacturing & Delivery

We build the machine with care and quality checks at each step. After that process we send it to your site fast and safely with full papers and guides. We also give installation help and a start-up guide so you can begin immediately.

Custom Cases for Smart Wire Processing Machines

Industrial Automation Wire Harness

We made a special harness for a large plant with our automatic wire cutting and stripping machine. It saved time and cost. It gave clean ends and a fast install. It also cut the defect rate and raised worker safety for the team.

New Energy & EV Wire Harness

We built a high-voltage harness for an EV maker using our wire processing systems. It passed strict tests and ran well in the field. It also allowed new designs with no delay and smoother builds.

Medical Devices Wire Harness

We used our automatic stripping and crimping machine to prepare safe cables for medical gear. It kept each piece sterile and ready. It also reduced manual labor and saved lab time and money.

Household Appliances Wire Harness

We cut and stripped home device wires with our wire cutting and stripping machine to speed up production. It gave neat and safe wires in every batch. It also lowered the cost per unit and improved the quality.

3C Electronics Wire Harness

We delivered micro harnesses with our automatic wire cutter machine for a gadget brand. It gave them stable and fine parts that fit right. It also gave them faster market entry with less rework.

Automotive Wiring Harness

We used our wire machines to make strong harnesses for car parts. It cut costs and time for the client. It also improved the quality score and warranty results for their products.

Why Choose VIMFUN

For more details and full product specs, visit the website of VIMFUN. Our wire processing machine and wiring machines are trusted by global brands. We give all buyers top tools, a fair price, and complete help. VIMFUN also offers fast support, spare parts, and training. VIMFUN is a one-stop for all wire machines needs.

FAQ

- What is the primary use of a wire processing machine?

It cuts, strips, and prepares wires and tubes quickly and carefully. It also lowers waste and improves the quality of each job.

- Can these machines handle many wire sizes?

Yes, these wire machines adjust for small and large wires with no stop, and store your settings for next time.

- Are the machines safe for medical device wires?

Yes, our wire processing machine systems give clean, sterile cuts with care and meet health rules and standards.

- Where can I buy these machines?

Check VIMFUN’s website for full details and order info. VIMFUN also gives demos and videos to show us.

- Do you offer custom harness work?

We build custom harnesses for many sectors using our wire processing machines with skill and speed. We also give design advice, after-sales help, and training for your team.