Custom Case

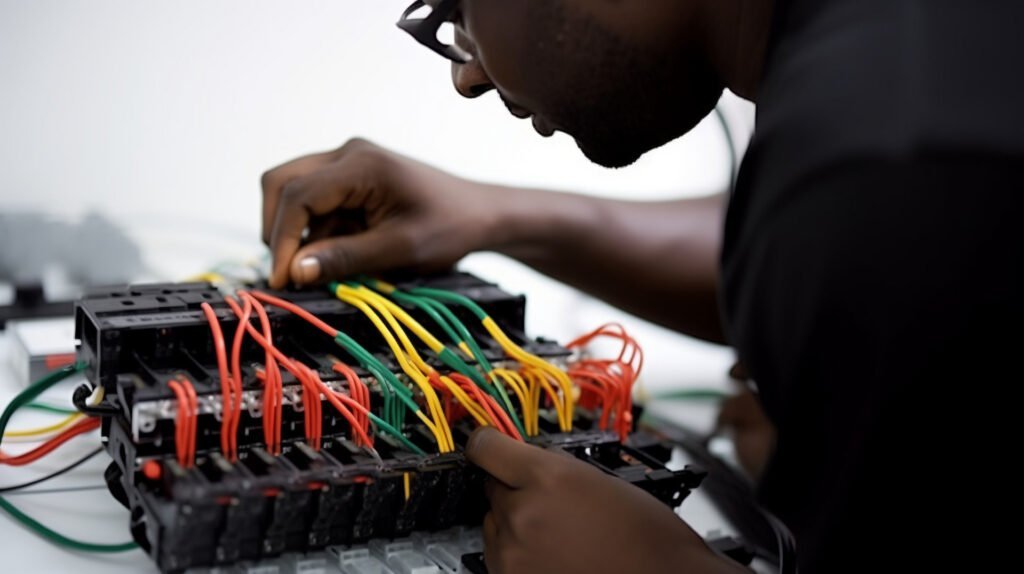

In 2020, a leading new energy vehicle manufacturer commissioned VIMFUN to design a customized wire harness processing solution for mass production of battery packs, charging modules, and electric drive systems.

Our engineering team integrated fully automatic cutting and stripping machines, terminal crimping stations, and online electrical testing systems to ensure precise lengths, consistent crimp quality, and stable production cycles. After installation, production efficiency increased significantly, and product consistency was ensured.

Subsequent upgrades included quick-change tooling, non-damaging wire feeding, and automatic bundling and labeling, further reducing manual intervention and enabling fully traceable production. This solution has provided the client with a long-term competitive edge in EV wire harness manufacturing.

Manufacturing · Customized Medical Devices Wire Harness Solutions

From concept to completion, we provide tailored wire harness automation solutions for medical devices, covering applications such as diagnostic equipment, patient monitoring systems, imaging devices, and surgical instruments. Our engineering team works closely with clients to transform complex wiring requirements into efficient, high-precision production systems. Whether you require a full-scale production line or specialized process optimization, we ensure precision, reliability, and compliance with strict medical manufacturing standards at every stage

Requirement Confirmation

Design & Validation

Technical Agreement

Manufacturing & Delivery

Delivery & Installation

Once the customized new energy and EV wire harness production equipment has completed manufacturing and testing, we conduct multiple full-process trial runs before shipment to ensure all stations operate in stable coordination and that the cycle time meets automotive and electric vehicle manufacturing standards.

The equipment is packaged with shockproof and moisture-proof protection suitable for industrial production environments, and professional logistics is arranged for safe delivery to the customer’s site, ensuring readiness for immediate production startup.