Industrial businesses need fast speeds every day. Each cut must also be clean and even. With the help of automated wire cutting machines, factories can easily reach these goals. It works for a long time. It keeps its exact size and shape on every wire. This is very important for assembly lines that make a lot of things. The speed at which workers work changes. Different people can do different kinds of work.

The stability of a machine does not change. Being tired is not a problem. It stays on track. One benefit is less waste from wires. The daily cost goes down too. In many factories, automated systems are becoming necessary. You can quickly pick up these machines. They don’t put your health at risk either. People of all ages can easily understand them because of this.

Mass Production Needs Automatic Wire Cutting

For mass production, fast transportation is very important. Time is important. An automated wire cutting machine is used to make sure that production never stops. It straightens the wire before cutting it. Then, the wire is cut cleanly. The result is wires that are cleanly cut off. Keeping a clean finish makes it easier to do other things. When you cut the wire by hand, it is likely to bend. It can also make things uneven in length. Machines get rid of these problems. They make things easier for workers. They also lower the number of mistakes. Fewer mistakes mean less loss. This is why big factories prefer machine tools over hand tools.

Key Features of Industrial Automatic Wire Cutting Machines

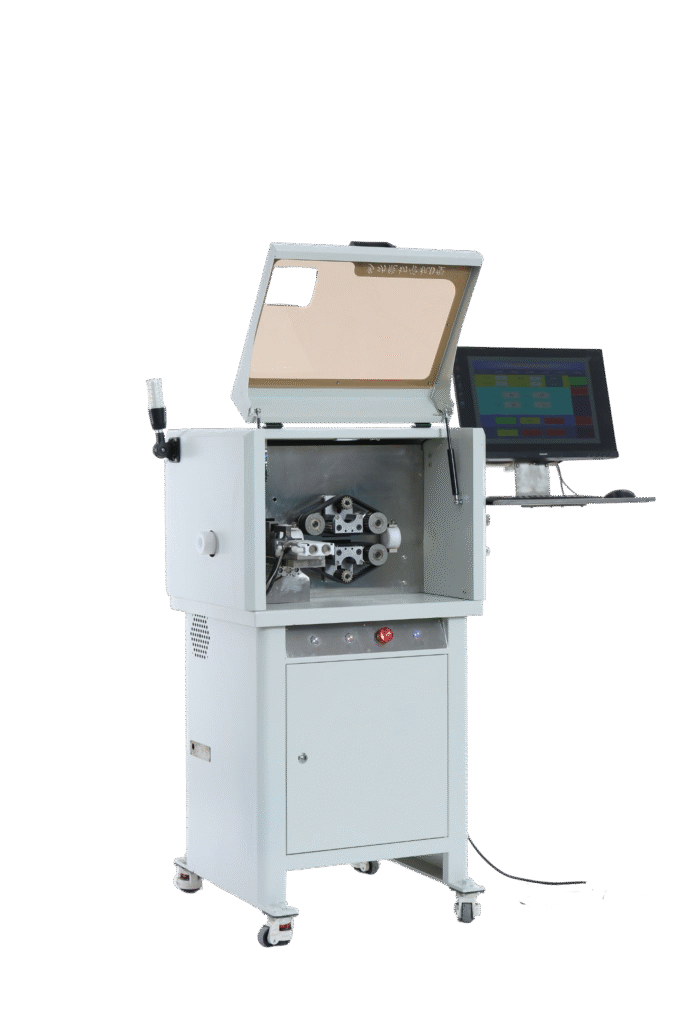

This machine’s game is strength. They won’t mind working long hours. A machine with strong rollers inside is used to automatically cut and strengthen wire. These rollers keep the wire from bending at all. Smart sensors control how long the cut is. Digital panels show clear data. Touch displays make setup easier. Use safety covers to keep your hands and fingers safe. The whole thing works perfectly. So, output stays fast. The quality is also kept up. Strong construction means that machines can go longer without needing maintenance.

Benefits for Large-Scale Manufacturing Units

Big factories need to have a good work-life balance. They need both speed and control. It’s great that an automated wire cutter and straightener can do two things at once. It cuts wire quickly. It keeps the length of the wire the same. No more work needs to be done. There are also fewer levels of scrap. While working, power use stays low. The noise level is also very low. Workers say they feel less tired during their shifts. Managers may notice better production every day. Planning production becomes simple.

Materials Supported by Automatic Wire Cutting Systems

Modern wire cutting machines can support a lot of different kinds of materials. A lot of people use copper wire. It’s also easy to work with aluminum wire. Steel wire blades should be stronger. Some machines can also cut tubing. The price of a wire saw cutting machine may change depending on the types of materials used. More valuable machines can handle more materials. In the long run, the benefits are very big. A single machine can take the place of some tools. This cuts down on the need for storage and cash. The factory’s workflow is also better.

Quality Control in Automatic Wire Cutting

Quality should come first for every product. Wire straightening and cutting machine makers are experts at making machines that have quality checks built in. Sensors keep a close eye on every move. The system will let the operator know whenever the length of the wire changes. This catches bad batches early on. The factory’s reputation is safe. Clean cuts later make the joint stronger. Safe couplings make sure that the end products are safe. This gives factories the confidence they need to meet quality standards.

Cost Efficiency and Production Savings

When you buy an automated wire cutting machines, you are making an investment. But you’ll see savings right away. At first glance, the cost of a wire straightening and cutting machine might seem too high. Over time, the cost of labor goes down. Wires also drop debris. Every day, production goes up. People are still able to control how they use power. The costs of upkeep are low. After a while, this gadget will pay for itself. Many plants see their profits go up after a few months.

Safety and Easy Operation for All Users

We put ease of use first. Use touch panels to learn the ropes quickly. You can easily see the buttons because they are big. You can read all of the signs. Safety guards protect all sharp edges. There is a safety style for wire saw stone cutting machines that is also used by wire machines. This is how to keep your hands safe. Training takes very little time. Workers quickly gain confidence. Safe machines make the workplace more comfortable.

- HW-8030HY Heavy-Duty Wire Stripping Machine with Touchscreen

The HW-8030HY is all about hard work. It handles heavy cables with ease. The touchscreen is bright and easy to see and use. You can change the settings in no time. The wire stripper cutting bending machine works quickly. It keeps the cutting length exactly right. It works well with strong lines. You don’t have to worry about it getting too hot during long shifts. Every day, a lot of factories use this model to make a lot of things.

- HW-B Advanced Cable Tubing Cutter with Multi-material Support

The HW-B model can cut wires and tubes. The cuts in the PVC tubes are neat. It also tears through rubber. It’s not hard to work with soft metals. This machine can help you save floor space. A single system can handle multiple tasks at once. It works well on assembly lines that move quickly. It makes the process flow more smoothly. It’s easy to get rid of clutter. We can keep things safe and clean this way.

- HW-D Digital Tube Cutter for Heat Shrink and PVC Tubes

The HW-D cutter’s main focus is on accuracy. It cuts tubes the same way every time. The length stays the same with each cut. Digital controls make things more accurate. It’s easy to use heat-shrink tubing. It also works with PVC tubing. This is very helpful for the jobs of wiring and insulating. When putting together tubes, clean cuts are very important.

- HW-8120X Precision Wire Stripping Machine with Rotary Blade

The HW-8120X is great for working with thin, small cables. The rotating blade makes cutting easy. The cores of the wires are not affected. That is very important for doing good electrical work. It keeps the pace of the stripping steady. On top of that, it’s fast. This wire straightening and cutting machine for sale is a great choice for factories that value accuracy.

Choosing the Right Machine for Your Factory

Different factories have different needs. Some factories need quick speeds with the wire cutting machines. Some need for exactness. Not everyone can live without both traits. Think about how thin the wire is. Think about the kind of material. Think about what you want to accomplish today. You can find a list of reputable companies that make machines for straightening and cutting wire. Look at each model very carefully. Choose the device that works best for your job.

Comparing Recommended Machines

| Machine Model | Main Use | Control Type | Best For |

| HW-8030HY | Heavy wire stripping | Touchscreen | High load work |

| HW-B | Wire and tube cutting | Digital | Multi-material lines |

| HW-D | Tube cutting | Digital panel | Heat shrink tubes |

| HW-8120X | Precision stripping | Rotary blade | Thin wires |

VIMFUN provides reliable automatic wire cutting machine solutions. Each machine is tested before delivery. Customer support is strong. Spare parts are easy to find. User guides are simple to follow. The website shows full machine details. Buyers can compare models easily. This helps make smart buying choices. Many factories grow faster with VIMFUN machines.

FAQs

- What is an industrial automatic wire cutting machine?

It is a machine that automatically straightens and cuts wire. It works fast without manual effort.

- Can these machines handle mass production?

Yes. They are built for long hours and continuous output.

- Are these machines safe for workers?

Yes. They include safety guards and simple controls.

- Do they support different materials?

Yes. Many machines support copper, aluminum, steel, and tubes.

- Where can I find reliable machines?

You can explore trusted automatic wire cutting machine models on the VIMFUN website.