An industrial automatic cutting machine needs to be built well, have a steady power supply, and a steady flow in order to work well for a long time. This type of machine needs to use a steady but gentle force to keep the cuts clean, sharp, and strong. As long as the power stays on, the cuts stay the same from start to finish, which gives workers confidence at every stage of the process.

The job is also safe because there is no chance that the tool or wire will be damaged by a jump or shock. Stable flow protects the fragile parts inside from getting too hot too quickly. The machine can run for a long time without needing any maintenance because it has easy-to-use controls and settings. This steady and smooth method also saves money because it needs fewer repairs.

Importance of Stable Power in Automatic Cutting Machine

The shop needs stable power to make sure that every cut is slow, even, and calm when working with different types of tubes, wires, rods, and sleeves. When pushing on soft tubes, use a little force. When pushing on stiff wires, use a lot of force. When pushing on metal rods, use a steady push. With smooth power, every type is cut exactly and safely.

When the power doesn’t jump, the parts don’t break down quickly. It is possible to keep a blade’s edge sharp for a lot longer. Turn down the heat. There is less waste. Using this can help stores save money, time, and keep their work flow healthy. When electricity is more reliable, people can get more work done in a day because there are fewer mistakes, delays, and interruptions.

How to Pick the Best Unit

- Check the wire’s gauge and material.

- Check the wall of the tube and how it feels.

- Check to see if you need to cut or bend.

- Check the speed you want.

Use slow units for easy tasks. Use quick units for heavy weights. Fine units are best for small, delicate, or tight tasks. Using the right tool for the job will give you a long life, a clean flow, and a safe place to work.

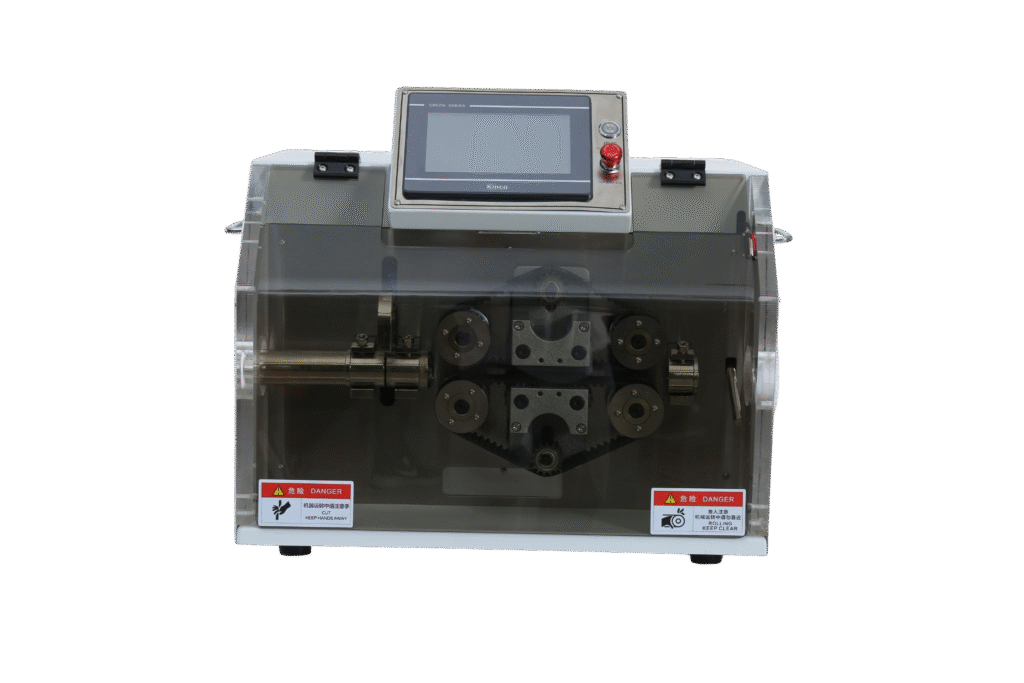

The Power of New Touch Panels

Using the automatic cutting machine unit is easy because of modern touch displays. The panel shows the speed, heat, load, and flow here. To set the cut, just tap once. Tap again to choose the length. Tap again to change strips. Everything stays simple with just one screen that isn’t cluttered. With the help of the panel, you can learn the ropes quickly. With its help, skilled users can work faster and safer. Every touch makes the job go smoothly.

Top 4 Automatic Cutting Machines

VIMFUN has put together a list of the best automatic cutting machine. These units use clean force and expert skill to cut cable, wire, tube, sleeve, and other materials. Their design puts ease of use and long-term use first.

- HW-8030HY Heavy-Duty Wire Stripping Machine with Touchscreen

This HW-8030HY tool strips wire by pulling on it with a strong and steady force. It will work no matter how thick or hard the wire is. A strong frame keeps the wire stable while sharp blades cut through debris. You can change the strip’s speed, length, and depth with a few taps on the touchscreen. New employees can use this to their advantage. This program is great for businesses of all sizes because it runs for a long time and doesn’t slow down. It cuts down on waste while keeping the cutting steady.

- HW-B30P Corrugated Tube Cutter with Longitudinal Slit Function

This HW-B30P equipment makes it easier and safer than ever to cut corrugated tubes. It also cuts a big hole that stops the tube from getting too big. This is good for groups of cables, bundles of wires, and parts of cars. This tool’s strong grip makes it easy to crush the tube. It protects the ribs of the tube by using a soft force. The slit is still smooth and not broken. This makes it easy for workers to move wires.

- HW-C High-Precision Tube Cutting Machine for Braided Sleeves

When this HW-C machine cuts braided sleeves, there can’t be any fraying or sharp edges. Little wheels with lights on them gently but firmly hold on to the sleeve. The wheels move slowly, which lets the blade make precise cuts. This is the best way to get precise sleeve cuts for your tech lab, cable shop, or aviation shop. It makes things run more smoothly, saves time, and boosts production.

- HW-8030HYJ Multi-core Cable Stripping Machine with High Accuracy

This HW-8030HYJ tool safely removes many-core cables. It protects each core without hurting the inner shield or mesh. It uses both sharp blades and strong clamps to hold the cable in place. With a clear screen and a few taps, the user can easily change each level. The lines in the strip stay clean, short, and wavy. This tool is great for a lot of businesses that use big cable sets.

Automatic Cutting Machine: Key Units

| Model | Best Use | Main Gain |

| HW-8030HY | Hard wire strip | Fast strip, clean edge |

| HW-B30P | Corrugated tube | Slit cut, smooth line |

| HW-C | Braided sleeve | Fine tube cut |

| HW-8030HYJ | Multi-core cable | High strip skill |

Choose VIMFUN for Automatic Cutting Machine

VIMFUN builds strong and innovative automatic cutting machines. They utilize new technology and clean power systems that ensure each cut is clean and safe. Each unit undergoes rigorous tests to demonstrate its capabilities. They guide each user with clear help, and they offer fast support when needed. Their tools last long, save costs, and keep shops safe.

FAQ

- How long does an auto cut unit work?

It can work long hours with stable power.

- Can I cut a soft tube?

Yes. Use an automatic plastic tube cutting machine or a soft tube tool.

- Can I strip many wires at once?

Yes. Use an automatic wire cutting and stripping machine.

- What if I need fine tube cuts?

Pick an automatic tube cutting machine with high skill.