Latest Products

HW-C High-Precision Tube Cutting Machine for Braided Sleeves

Key Highlights

HW-C Efficient Braided Sleeve Cutting

📌 Cutting range: Ø1–36mm

📌 Accuracy: ±0.2–0.5% (material-dependent)

📌 Speed: 50–400 pieces/min

📌 7” Buker true-color touchscreen

📌 Caterpillar feeding for zero material damage

Why Choose VIMFUN Equipment

Advanced automation solutions trusted worldwide for precision, efficiency, and reliability.

Delivering precision-engineered equipment across automotive, electronics, new energy, and medical industries.

-

15+ Years Experience

Proven expertise and professional solutions in wire processing automation.

-

High Precision & Reliability

Cutting accuracy up to ±0.20 mm for stable long-term performance.

-

Global Service

Trusted by customers in 30+ countries with responsive technical support.

-

OEM/ODM Customization

Tailored equipment solutions designed to match your unique production needs.

Overview

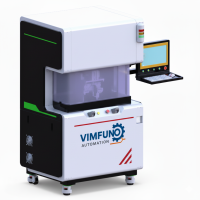

The HW-C High-Precision Tube Cutting Machine is engineered for fast, accurate cutting of Ø1–36mm hoses and braided sleeves. Equipped with a motion control board and a 7” Buker true-color touchscreen, it offers intuitive operation and efficient digital control. Powered by a 2KW servo motor and a caterpillar feeding system, it ensures reliable processing of various hose materials. With a cutting accuracy of ±0.2–0.5% (material-dependent) and speeds up to 50–400 cuts per minute, the HW-C is ideal for high-volume production environments like cable sleeve and industrial hose manufacturing.

Key Features

- Wide Cutting Range: Processes Ø1–36mm hoses and braided sleeves.

- High Precision: Cutting accuracy of ±0.2–0.5% (material-dependent) for quality results.

- Servo Cutting System: 2KW Hechuan servo motor for powerful, precise cuts.

- Flexible Feeding Options: Standard 60 stepper motor, optional servo motor upgrade.

- Caterpillar Feeding: Smooth feeding to prevent material damage.

- Standard Blade: Uses 18mm utility blade for easy replacement and maintenance.

- Intuitive Touchscreen: 7” Buker true-color touchscreen for user-friendly operation.

- High Output: Cutting speed of 50–400 pieces/min (length-dependent).

- Compact Design: Measures 105×65×130cm, suitable for small workshops.

- Premium Components: Features high-quality parts from Hechuan, Delta, and Hewang.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model | HW-C |

| Cutting Range | Ø1–36mm hoses |

| Cutting Method | Motor-driven (18mm utility blade) |

| Cutting Power | 2KW Servo Motor |

| Feeding Motor | 60 Stepper Motor (optional servo) |

| Feeding Method | Caterpillar Feeding |

| Accuracy | ±0.2–0.5% (material-dependent) |

| Speed | 50–400 pieces/min (length-dependent) |

| Power Supply | 220V, 50–60Hz |

| Total Power | 1800W |

| Touchscreen | 7” Buker True-Color |

| Controller | Hewang Custom 5-Axis Control |

| Dimensions | 105×65×130cm |

| Weight | 135kg |

| Compatible Materials | Braided sleeves, hoses, PVC, silicone |

Applications

- Cable Sleeve Manufacturing: Provides fast, precise cuts for cable protection sleeves.

- Automotive Hose Processing: Meets cutting needs for automotive hoses and sleeves.

- Industrial Automation: Supports tubing processing for automated equipment.

- Electronics Cable Management: Delivers high-precision sleeve cutting for electronics.