Latest Products

HW-B60 Large-Diameter Corrugated Tube Cutter

High-Precision Cutting for Large-Diameter Corrugated Tubes

HW-B60 delivers stable pneumatic cutting for tubing up to Ø60 mm, optimized for industrial conduit applications.

📌 Cutting Range: Ø5–60 mm

📌 Cutting Tolerance: ±0.5 + L×0.002 mm

📌 Up to 60 pcs/min

📌 PLC + 7” Touchscreen

📌 Optional slitting function available

Why Choose VIMFUN Equipment

Advanced automation solutions trusted worldwide for precision, efficiency, and reliability.

Delivering precision-engineered equipment across automotive, electronics, new energy, and medical industries.

-

15+ Years Experience

Proven expertise and professional solutions in wire processing automation.

-

High Precision & Reliability

Cutting accuracy up to ±0.20 mm for stable long-term performance.

-

Global Service

Trusted by customers in 30+ countries with responsive technical support.

-

OEM/ODM Customization

Tailored equipment solutions designed to match your unique production needs.

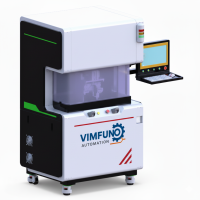

Overview

The HW-B60 is a precision-engineered cutting machine designed for high-efficiency processing of large-diameter corrugated tubes. With support for cutting ranges up to Ø60 mm, it is ideally suited for wire harness protection applications in the automotive, electrical, and automation industries. Its robust drive system and 7-inch touchscreen control provide stable, accurate, and user-friendly operation.

Key Features

Large Cutting Range

Handles corrugated tubes from Ø5 mm to Ø60 mm, suitable for heavy-duty conduit processing.

High-Speed Cutting

Up to 60 pcs/min, ensuring high productivity for industrial batch production.

Pneumatic Blade with Precision Tolerance

Cutting tolerance maintained at ±0.5 + L×0.002 mm for consistent output.

Rotary Blade Upgrade Optional

Compatible with slitting module for longitudinal slits as required.

Smart Touchscreen Operation

7” Kinco touchscreen with PLC control for easy setup and parameter adjustment.

Durable Component Integration

Uses high-quality parts from established brands for long-term stability.

Stable Feeding Mechanism

Stepper-motor-driven synchronous belt with guide rail prevents tube deformation or deviation.

Low Maintenance Design

Simple mechanical structure and modular integration reduce downtime and service frequency.

Applications

Ideal for:

Automotive conduit tube cutting

Industrial cable protection sleeve trimming

Large-diameter electrical conduit processing

Automation tube preparation for robotic systems

Technical Specifications

Parameter | Specification |

|---|---|

Model | HW-B60 |

Cutting Range | Ø5 – Ø60 mm |

Cutting Speed | Up to 60 pcs/min |

Cutting Tolerance | ±0.5 + L×0.002 mm (L = cutting length) |

Cutting Method | Pneumatic blade (60 mm stroke) |

Control System | PLC + HMI (7” Kinco touchscreen) |

Drive Type | Stepper motor (60BYG/86BYG), PLC-controlled |

Feeding System | Synchronous belt + guide rail |

Slitting Function | Optional longitudinal slitting module |

Power Supply | 220V / 50Hz |

Air Pressure | ≥0.6 MPa |

Dimensions | 72 × 50 × 60 cm |

Weight | 94 kg |

Component Brands | 创谊, 星辰, 明纬, HCH, 万文 |