Latest Products

HW-B30X Automatic Conduit Cutter for Corrugated Sleeves

The HW-B30X is ideal for applications in:

-

Automotive wire harness conduit cutting

-

PVC and PE tube processing

-

Electrical cable protective sleeve trimming

-

Automation and robotic tubing systems

Why Choose VIMFUN Equipment

Advanced automation solutions trusted worldwide for precision, efficiency, and reliability.

Delivering precision-engineered equipment across automotive, electronics, new energy, and medical industries.

-

15+ Years Experience

Proven expertise and professional solutions in wire processing automation.

-

High Precision & Reliability

Cutting accuracy up to ±0.20 mm for stable long-term performance.

-

Global Service

Trusted by customers in 30+ countries with responsive technical support.

-

OEM/ODM Customization

Tailored equipment solutions designed to match your unique production needs.

Overview

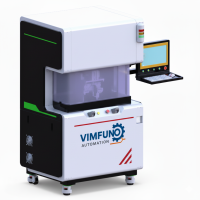

The HW-B30X is a high-precision rotary-blade conduit cutting machine engineered for clean and efficient cutting of corrugated sleeves and PVC tubes. Designed with a servo-driven rotary cutting system and PLC touchscreen control, it ensures consistent accuracy and high throughput—ideal for wire harness processing, industrial automation, and conduit preparation lines.

Key Features

Wide Cutting Range

Supports outer diameters from Ø5 mm to Ø42 mm, with precision rotary cutting ideal for rigid and flexible corrugated tubes.

Rotary Cutting with Servo Drive

Equipped with a 400W servo motor to drive rotary blades, ensuring clean, burr-free cuts without deforming the tube.

Touchscreen Interface

7-inch color touch panel (JiuRui brand) allows intuitive parameter adjustment and real-time production monitoring.

Precision Control

Length tolerance reaches L×0.001±0.2 mm for PVC tubes under 1000 mm, suitable for applications requiring stable repeatability.

High Productivity

Cutting speeds range from 10 to 60 pcs/min (based on length), suitable for medium- to large-scale production.

Digital Tube Clamping

Digitally adjustable pressure ensures secure tube holding without damage or slippage.

Durable Component Configuration

Built with branded components such as Xinje servo motor, MGN9H linear guides, HCH bearings, and custom PLC system for long-lasting performance.

Compact Footprint

Machine dimensions: 47 × 67 × 58 cm; Weight: 78 kg. Easily integrates into existing workstations.

Technical Specifications

Specification | Value |

|---|---|

Model | HW-B30X |

Control System | PLC + Touchscreen |

Cutting Method | Rotary Cutting |

Feeding System | Stepper Motor |

Cutting Stroke | 8 mm |

Tube Clamping | Digitally Adjustable |

Rotary Motor | 400W Servo Motor |

Cutting Diameter | Ø5–Ø42 mm |

Cutting Tolerance | L × 0.001 ± 0.2 mm (PVC <1000mm) |

Cutting Speed | 10–60 pcs/min |

Air Pressure | 0.5–0.7 MPa |

Power Supply | 220V 50/60Hz |

Power Consumption | 750W |

Machine Size | 47 × 67 × 58 cm |

Net Weight | 78 kg |