Latest Products

HW-B30 Corrugated Tube Cutting Machine for Cable Conduit

HW-B30 delivers clean, accurate cuts for PVC and PE corrugated tubes up to Ø30 mm, designed for stable, high-efficiency conduit processing in wire harness and automation industries.

📌 Key Highlights:

-

📌 Cutting range Ø1–30 mm(optional Ø30–45 mm available)

-

📌 Tolerance within ±1% for consistent accuracy

-

📌 Up to 60 pcs/min cutting speed

-

📌 7” touchscreen for intuitive operation

-

📌 Electric PLC-controlled drive for smooth, burr-free results

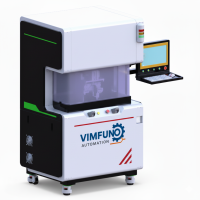

Why Choose VIMFUN Equipment

Advanced automation solutions trusted worldwide for precision, efficiency, and reliability.

Delivering precision-engineered equipment across automotive, electronics, new energy, and medical industries.

-

15+ Years Experience

Proven expertise and professional solutions in wire processing automation.

-

High Precision & Reliability

Cutting accuracy up to ±0.20 mm for stable long-term performance.

-

Global Service

Trusted by customers in 30+ countries with responsive technical support.

-

OEM/ODM Customization

Tailored equipment solutions designed to match your unique production needs.

Overview

The HW-B30 is a high-precision electric cutting machine specifically engineered for corrugated tubes and cable conduits ranging from Ø1 mm to Ø30 mm. Featuring a compact design, full-color touchscreen interface, and advanced PLC control system, it ensures clean, accurate, and efficient cuts without damaging the tube surface. Whether for automotive harnesses, control panels, or cable protection sleeves, HW-B30 offers unmatched reliability and performance for tube processing applications.

Key Features

📌 Broad Cutting Range

Supports outer diameters from Ø1 to Ø30 mm (optional Ø30–Ø45 mm version available), making it compatible with various corrugated tubes and conduits.

📌 High Cutting Accuracy

Maintains cutting tolerance within ±1%, ideal for applications requiring consistent lengths and clean edges.

📌 Touchscreen Control Panel

Equipped with a 7” color touchscreen, the interface allows real-time parameter adjustment and simplified operation, even for first-time users.

📌 Intelligent Motion Control

Controlled by a stable PLC system with support for customizable programs, delivering excellent repeatability and processing logic.

📌 Efficient Production Speed

Cutting speed ranges from 10 to 60 pieces per minute depending on length and material, enabling high throughput in production environments.

📌 Compact and Durable Build

Machine dimensions are 60 × 50 × 55 cm, suitable for benchtop placement. Built with industrial-grade materials for long-term durability.

📌 Integrated Sensor System

Utilizes both photoelectric and proximity sensors to ensure precise tube positioning and prevent miscuts.

📌 Low Maintenance

The modular design, combined with electric actuation and minimal air components, allows easy maintenance and low operational cost.

📌 Customization Ready

Supports custom tube diameters, length settings, and cut shapes upon request. Sample testing is available to verify compatibility.

Technical Specifications

Item | Value |

|---|---|

Model | HW-B30 |

Tube Diameter Range | Ø1–Ø30 mm (Optional: Ø30–Ø45 mm) |

Cutting Tolerance | ±1% |

Drive Type | Electric cutter with PLC motion control |

Touchscreen | 7” full-color display |

Cutting Speed | 10–60 pcs/min (depending on length) |

Power Supply | 220V, 50/60Hz |

Power Consumption | 300W |

Dimensions | 60 × 50 × 55 cm |

Net Weight | 70 kg |

Customization Options | Available for special tube sizes and shapes |

Applications

The HW-B30 is widely used in the processing of:

Corrugated tubes for automotive wiring harnesses

Flexible conduits in control panels and electrical cabinets

Protective tubing for robotics, machinery, and automation systems

PVC and PE conduit used in home appliances and industrial wiring setups

It is an ideal solution for cable harness manufacturers, OEM factories, and automation workshops that require high-speed, clean tube cuts without deformation or burrs.