Latest Products

HW-8240 High-Speed Cable Stripper for Industrial Use

High-Efficiency Stripping for Large Industrial Cables

HW-8240 delivers accurate rotary stripping and clean cutting for cables up to 240 mm²—built for industrial-scale processing.

📌 Up to 1000 pcs/hour

📌 Cutting tolerance: ±0.002 × L

📌 Rotary blades for thick insulation

📌 Servo-driven stability

📌 7” touchscreen operation

Why Choose VIMFUN Equipment

Advanced automation solutions trusted worldwide for precision, efficiency, and reliability.

Delivering precision-engineered equipment across automotive, electronics, new energy, and medical industries.

-

15+ Years Experience

Proven expertise and professional solutions in wire processing automation.

-

High Precision & Reliability

Cutting accuracy up to ±0.20 mm for stable long-term performance.

-

Global Service

Trusted by customers in 30+ countries with responsive technical support.

-

OEM/ODM Customization

Tailored equipment solutions designed to match your unique production needs.

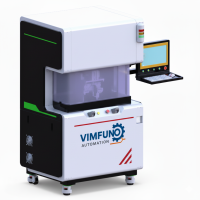

Overview

The HW-8240 is a high-speed, fully automatic wire stripping and cutting machine designed for large cross-section cables up to 240 mm². Equipped with precision rotary blade technology and intelligent touchscreen control, it delivers superior stripping accuracy and processing efficiency for industrial applications.

Key Features

Wide Cable Range

Handles wire cross-sections from 10–240 mm², ideal for heavy-duty industrial use.

Rotary Blade Stripping

Integrated rotary blade system provides clean, damage-free stripping for thick insulation layers.

Precision Cutting

Cutting tolerance within ±0.002 × L ensures accuracy across all wire lengths.

Touchscreen Interface

7-inch full-color touch display with user-friendly interface for parameter control and diagnostics.

High-Speed Output

Capable of processing up to 1000 pcs/hour, depending on wire length and diameter.

Servo Motor Drive

Enhanced stability and torque control via high-performance servo motor.

Optional Modules

Customizable for specialized wires; supports front/rear stripping modes.

Compact Design

Integrated structure with optimized footprint for production line adaptability.

Technical Specifications

Parameter | Specification |

|---|---|

Wire Range | 10–240 mm² |

Stripping Length | Front: 1–800 mm / Rear: Optional |

Cutting Length | 1 mm–99,999.99 mm |

Cutting Tolerance | ±0.002 × L |

Drive System | Full Servo System |

Display | 7” Touchscreen |

Blade Type | Rotary Cutter |

Power Supply | 220V / 50Hz ±10% |

Productivity | ~1000 pcs/h (depends on cable size) |

Dimensions | 1000 × 800 × 600 mm |

Applications

Ideal for power cable assembly in EVs, industrial control cabinets, heavy equipment manufacturing, and energy infrastructure projects requiring precise and reliable large wire processing.