Latest Products

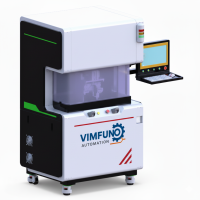

HW-8150Q High-Efficiency Automatic Cable Cutting Machine

Product Model: HW-8150Q Cutting Machine

Function: Fully automatic cutting and stripping of wires and cables

Stripping Range: 1–150 mm² (customization available for sizes above 150 mm²)

Net Dimensions: 900 mm × 710 mm × 560 mm

Why Choose VIMFUN Equipment

Advanced automation solutions trusted worldwide for precision, efficiency, and reliability.

Delivering precision-engineered equipment across automotive, electronics, new energy, and medical industries.

-

15+ Years Experience

Proven expertise and professional solutions in wire processing automation.

-

High Precision & Reliability

Cutting accuracy up to ±0.20 mm for stable long-term performance.

-

Global Service

Trusted by customers in 30+ countries with responsive technical support.

-

OEM/ODM Customization

Tailored equipment solutions designed to match your unique production needs.

The HW-8150Q is a fully automatic cutting and stripping solution built for high-load

cable applications. Supporting wire cross-sections up to 150 mm² (and customizable beyond), it delivers superior processing performance for thick cables with precise control, intuitive operation, and modular expandability—ideal for automotive, power supply, and industrial applications.

Key Features

● Broad Wire Range Support

Handles cables including PVC, power cables, and sheathed wires with cross-sections from 1–150 mm². Customization available for larger cables.

● Precision Cutting Performance

Cutting length from 1 mm to 99,999.99 mm, with a tolerance within ±0.002 × L (L = cutting length), ensuring consistent accuracy in mass production.

● Advanced Stripping Capability

Supports front-end stripping up to 800 mm, ideal for long terminal exposure; no rear stripping.

● Robust Feeding System

Uses a 16-wheel belt drive mechanism for no-scratch, no-indent cable feeding—preserves insulation even under high torque.

● Dual Motor Control System

Features a combination of servo motor cutter and stepper motor feeding for stable, high-speed output. (Optional upgrade to full-servo.)

● High Efficiency Throughput

Up to 1800 pieces per hour, depending on cable type and length.

● Industrial-Grade Blade

Equipped with imported high-speed steel blades, ensuring long-lasting sharpness and wear resistance.

● Intelligent Touchscreen Interface

Built with a 7” full-color touchscreen (Kinco) for easy parameter setup, status monitoring, and operational control.

● Compact Footprint, Factory Ready

Machine dimensions: 900×710×560 mm

Package size: 1000×810×760 mm

Power: 220V / 50Hz ±10%, 1.6KW

● Smart Automation Functions

Includes front-end full stripping with guide sleeve, stripping pressure control, encoder feedback, and auto wire infeed detection.

● Optional Add-Ons

Compatible with accessories such as cable collection clamps, mechanical unloading arm, storage racks (modular isolation required).

Technical Specifications

Parameter

Specification

Model

HW-8150Q

Display

7” Full-Color Touchscreen (Kinco)

Function

Fully automatic wire & cable cutting + stripping

Compatible Wires

Power cable, PVC, sheathed wire, etc.

Wire Range

1–150 mm² (customizable beyond)

Cutting Length

1–99,999.99 mm

Cutting Tolerance

≤ 0.002 × L

Stripping Length

Front: 1–800 mm; Rear: Not supported

Max Cable Diameter

Φ33 mm

Blade Material

Imported High-Speed Steel

Productivity

Up to 1800 pcs/h (depends on length & size)

Drive Method

Cutter: Servo motor; Feeder: Stepper motor

Feeding Method

16-wheel Belt Feed (no indentation/scratch)

Voltage

220V / 50Hz ±10%

Installed Power

1.6 KW

Full Load Current

18 A (min. required: 10 A)

Air Source

Not required

Machine Dimensions

900×710×560 mm

Package Dimensions

1000×810×760 mm

Application Scenarios

The HW-8150Q is ideal for heavy-duty cable cutting and stripping across industries such as:

Automotive wire harness

New energy equipment

Power supply & distribution systems

Industrial machinery manufacturing

Special Functions

Custom Cable Compatibility – Supports testing and adjustment based on customer samples

Smart Functions – Full stripping sleeve, encoder feedback, auto wire detection, pressure control

Modular Integration – Supports accessory expansion such as unloading arms and wire trays (modular isolation required)