Latest Products

HW-8030Y Large-Square Wire Computerized Stripping Machine

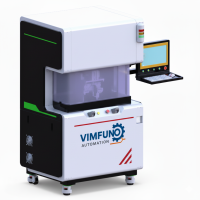

Model: HW-8030Y – Integrated Unit with Workbench

High-Quality Manufacturing: The HW-8030Y wire stripping machine is built using advanced automated assembly and precision machining techniques, ensuring stable performance and reliable operation.

Versatile Features: Designed for the full-automatic cutting and stripping of wires and cables, the HW-8030Y supports a stripping range of 1–30 mm², making it ideal for handling various cable diameters and insulation types. It also features intelligent recognition and high processing efficiency.

Wide Range of Applications: This machine is widely used in wire harness processing and assembly for home appliances, automotive systems, 3C electronics, new energy solutions, and medical device manufacturing.

Eco-Friendly Design: Developed with energy efficiency and environmental sustainability in mind, aligning with modern industrial standards.

Customization & Technical Support: The HW-8030Y supports function expansion and parameter customization to suit specific production line needs, backed by expert technical service and responsive after-sales support.

Why Choose VIMFUN Equipment

Advanced automation solutions trusted worldwide for precision, efficiency, and reliability.

Delivering precision-engineered equipment across automotive, electronics, new energy, and medical industries.

-

15+ Years Experience

Proven expertise and professional solutions in wire processing automation.

-

High Precision & Reliability

Cutting accuracy up to ±0.20 mm for stable long-term performance.

-

Global Service

Trusted by customers in 30+ countries with responsive technical support.

-

OEM/ODM Customization

Tailored equipment solutions designed to match your unique production needs.

High-Performance Wire Processing for Industrial Applications

The HW-8030HY is a high-precision, all-in-one computerized wire stripping machine designed for automatic cutting and stripping of various wire and cable types. Equipped with a 7-inch full-color touch screen and a modular structure, it ensures stability, efficiency, and ease of use for mass production lines in automotive, appliance, and control systems.

Key Features

Full Automation: Supports auto cutting and stripping for wire diameters ranging from 1mm² to 30mm².

Wide Wire Compatibility: Suitable for single-core wires, multi-core cables, shielded cables, and PVC-insulated wires.

High Cutting Precision: Tolerance within ±0.002 × L (L = cutting length).

Flexible Stripping Configurations:

Front: Outer jacket 10–150mm / Core wire 1–50mm

Rear: Outer jacket 10–80mm / Core wire 1–50mm

(Material dependent; actual results vary with wire sample.)

Max Outer Diameter: Up to Φ18mm.

Premium Blade Material: High-speed imported steel ensures clean and consistent cuts.

Production Speed: Up to 1000 pieces/hour (varies by wire length and diameter).

Drive System: 16-wheel drive with servo cutter head; optional servo feeding available.

No-Damage Feeding: Belt-fed mechanism avoids wire indentation or abrasion.

Mobility Design: Integrated working table with movable base for quick repositioning.

Technical Specifications

Parameter | Specification |

|---|---|

Model | HW-8030HY All-in-One |

Display | 7” Full-Color Touch Screen (Kinco) |

Stripping Range | 1–30 mm² |

Cutting Length | 1–99,999.99 mm |

Cutting Tolerance | ±0.002 × L |

Max Cable Diameter | Φ18 mm |

Drive Method | 16-wheel (Stepper feed + Servo blade) |

Throughput | Up to 1000 pcs/hour |

Blade Material | High-Speed Imported Steel |

Feeding Method | Belt Drive (No Cable Damage) |

Power Supply Components | Delta, HCH, Yadeke, Hiwin, Kinco |

Customization | Special wires supported via sample test |

Configuration Highlights

Servo motor: 400W (Hechuan, Zhejiang)

Stepper motors: 6 units (Changyi, Changzhou)

Motion Controller: Custom developed (Shenzhen)

Touch Screen: Kinco 7” color display

Linear Rails: EGH15 by Hiwin (Taiwan)

Transmission: Ball screw 2005 + 3M drive belts

Electrical components: Yadeke valves, Delta PSU, HCH bearings

Applications

Ideal for precision wire processing in:

Automotive harness manufacturing

Home appliance internal wiring

Control cabinet cable preparation

New energy sector (e.g., battery packs)

Consumer electronics

Customization & Support

Have special wire types or production needs? We offer:

Sample testing for special cables

Custom blade design & module adjustments

Full technical support and quick-response service