Latest Products

HW-8030HYJ Multi-core Cable Stripping Machine with High Accuracy

Precision Stripping for Complex Multi-Core Cables

HW-8030HYJ offers automated outer and inner sheath stripping for multi-core cables up to 30 mm². Ideal for high-precision wire harness processing.

📌 Up to 1000 pcs/hour

📌 Outer & inner sheath stripping in one cycle

📌 ±0.002 × L cutting accuracy

📌 7” color touchscreen with smart interface

📌 Robotic arm integration for streamlined operation

Why Choose VIMFUN Equipment

Advanced automation solutions trusted worldwide for precision, efficiency, and reliability.

Delivering precision-engineered equipment across automotive, electronics, new energy, and medical industries.

-

15+ Years Experience

Proven expertise and professional solutions in wire processing automation.

-

High Precision & Reliability

Cutting accuracy up to ±0.20 mm for stable long-term performance.

-

Global Service

Trusted by customers in 30+ countries with responsive technical support.

-

OEM/ODM Customization

Tailored equipment solutions designed to match your unique production needs.

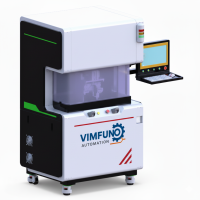

Overview

The HW-8030HYJ is a fully automatic wire and multi-core cable stripping machine, equipped with a 7-inch color touchscreen and robotic arm for enhanced automation. It supports the complete stripping of outer sheaths and inner cores in one cycle, making it ideal for complex wire harness processing in various industries.

Key Features

Multi-core Sheathed Cable Processing

Handles cables up to 30 mm² and supports up to 7-core sheathed wires with simultaneous outer and inner stripping.

Full-Automatic Cutting & Stripping

Complete stripping at both wire ends:

Front: outer sheath 10–150 mm, inner core 1–50 mm

Rear: outer sheath 10–80 mm, inner core 1–50 mm

Touchscreen Control

Kinco 7-inch color touchscreen for user-friendly and intuitive operation.

High Precision & Stable Feeding

±0.002 × L cutting tolerance with 16-wheel belt feeding system to prevent surface damage.

Adaptability & Customization

Accepts various wire types including PVC, power cables, and multi-core sheathed wires. Custom configurations available upon sample testing.

Reliable Component Build

Built with high-quality components including servo motors, ball screws, and linear rails from reputable brands such as Kinco, Hiwin, and Schneider.

Applications

Suitable for advanced wire harness production in home appliances, automotive, industrial equipment, and control panel manufacturing—particularly where complex multi-core cable processing is required.

Technical Specifications

Parameter | Value |

|---|---|

Model | HW-8030HYJ (Integrated with robotic arm) |

Display | 7” Color Touchscreen |

Stripping Range | 1–30 mm² (≤7-core sheathed cable) |

Cutting Length | 1–99,999.99 mm |

Cutting Tolerance | ±0.002 × L (L = cutting length) |

Stripping Length | Front: 10–150 mm (sheath), 1–50 mm (core)Rear: 10–80 mm (sheath), 1–50 mm (core) |

Feeding Method | Belt feeding with 16-wheel drive |

Drive System | Stepper feed, servo cutting (optional servo feed) |

Max Conduit Diameter | Φ18 mm |

Cutter Material | Imported High-Speed Steel |

Output | 1000 pcs/h (800 pcs/h for sheathed cable) |

Power Supply | 220V / 50Hz ±10% |

Installed Power | 1.6 kW |

Remarks | Customization available upon sample testing |