Latest Products

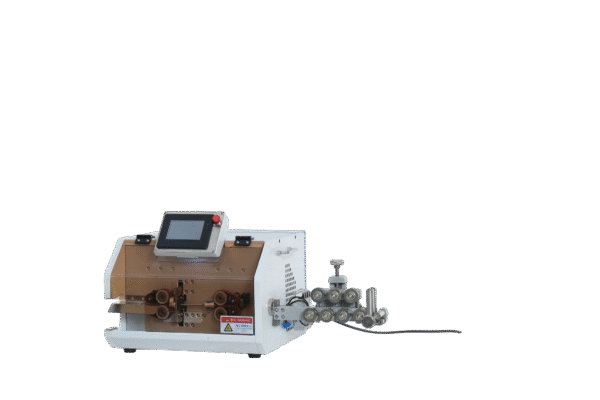

HW-8010 Computerized Wire Stripping Machine

High-Quality Manufacturing

Built with precision components and automated assembly, the HW-8010 ensures stable, durable, and reliable performance.

Versatile Features

Supports 0.5–10 mm² wire sizes and cutting lengths up to 99,999.99 mm. Features a 4.3” touchscreen for easy parameter control.

Wide Applications

Ideal for PVC wires, single-core wires, and cables used in appliances, automotive, and electronics industries.

Eco-Friendly Design

Engineered for energy efficiency and reduced waste, aligning with sustainable manufacturing standards.

Customization & Support

Offers sample testing and tailored solutions with expert technical and after-sales service.

Why Choose VIMFUN Equipment

Advanced automation solutions trusted worldwide for precision, efficiency, and reliability.

Delivering precision-engineered equipment across automotive, electronics, new energy, and medical industries.

-

15+ Years Experience

Proven expertise and professional solutions in wire processing automation.

-

High Precision & Reliability

Cutting accuracy up to ±0.20 mm for stable long-term performance.

-

Global Service

Trusted by customers in 30+ countries with responsive technical support.

-

OEM/ODM Customization

Tailored equipment solutions designed to match your unique production needs.

The HW-8010 is a high-performance automatic wire cutting and stripping machine, designed to handle a wide range

of wire types with precision and stability. Featuring a user-friendly 4.3-inch color touchscreen and robust

internal components, it is ideal for processing PVC wires, single-core wires, and various cable types.

Key Features

High-Precision Cutting & Stripping

Suitable for wire sizes from 0.5 to 10 mm², with cutting lengths from 1 mm to 99,999.99 mm and front-end stripping up to 100 mm.

Touchscreen Control

4.3-inch color touchscreen interface for intuitive operation and real-time parameter adjustments.

Efficient Throughput

Processes up to 1,000 pcs/hour depending on wire size and length.

Eight-Wheel Drive with Belt Feeding

Ensures stable wire feeding without indentations or surface damage.

Customizable for Special Wires

Compatible with custom configurations for irregular or special wire types—sample testing available upon request.

Technical Specifications

Parameter | Specification |

|---|---|

Model | HW-8010 Standard Version |

Display | 4.3” True Color Touchscreen |

Function | Automatic wire cutting and stripping |

Wire Types | Single-core, cable, PVC, etc. |

Stripping Range | 0.5 – 10 mm² |

Cutting Length | 1 – 99,999.99 mm |

Cutting Tolerance | ≤ 0.002 × L (L = cutting length) |

Front Stripping Length | 1 – 100 mm |

Rear Stripping Length | 1 – 60 mm |

Max Wire Diameter | Φ10 mm |

Tool Material | High-speed imported steel |

Production Capacity | Up to 1,000 pcs/hour |

Drive Method | 8-wheel silent hybrid stepper motor |

Feeding Method | Belt feed (no indentation or scratches) |

Customization | Special wires can be tested and adapted |

Standard Components List

No. | Component Name | Spec/Model | Brand | Origin | Qty |

|---|---|---|---|---|---|

1 | Color Touchscreen | 4.3” | Samkoon | Shenzhen | 1 |

2 | Motion Controller | Customized | Shenzhen | 1 | |

3 | Wear-resistant Drive Belt | 3M | Yite | Xiamen | 4 |

4 | Precision Ball Screw | 1204 | Custom | Zhejiang | 2 |

5 | Stepper Motors | — | Chuangyi | Changzhou | 5 |

6 | Driver | 6A Servo | — | Shenzhen | 5 |

7 | Transformer | 500W | Wanwen | Dongguan | 1 |

8 | Solenoid Valve | 6V210 | Airtac | Taiwan | 3 |

9 | Manifold Block | 3-port | Airtac | Taiwan | 1 |

10 | Photoelectric Sensor | — | Huazhikong | Shenzhen | 3 |

11 | Bearings | — | HCH | Ningbo | 53 |