Accuracy is the key component of any high-quality cutting job. When cuts are accurate, the Automatic Tube Cutting Machine simplifies and streamlines the process. Even the smallest size error can lead to waste. It might also slow down the queue as a whole. A high-speed cutting mechanism helps identify these problems early. It keeps repeating for the same amount of time.

This ensures that every tube is the same size. Employees feel more confident when results are predictable. Modern control instruments direct each step of the cut. Sensors measure the size both before and after cutting. As a result, automated cutting machine tubes are now used in many factories. As a result, time is saved. It helps reduce expenses. Also it helps with It also aids in daily maintenance of great quality.

Speed in Automatic Tube Cutting Machine Improves Output

There’s actually more to fast work than just working quickly. It also keeps the process consistent. When Automatic Tube Cutting Machine runs quickly, there is less waiting time. The stuff continues to move around. Advanced sensors keep track of every movement. The system calculates the tube length multiple times in a single cycle. Errors are reduced as a result. Waste swiftly declines. The usage of energy is also controlled. Workers don’t often have to stop the line. A sturdy tube cutting machine with an automated setup can operate for a long time. Its quality doesn’t change from day to night. This helps factories in achieving their daily targets.

Clean Cuts for Plastic Tubes

Plastic tubes need clean and gentle cutting. Too much heat can damage the edge. Too much force can cause the tube to bend. A fast blade with the correct pressure solves this issue. The cutting action stays smooth. Heat stays low during the cut. The edge stays neat and even. A reliable automatic plastic tube cutting machine ensures the tube’s shape remains intact. It works well with soft plastic. It also works with hard plastic. Noise stays low during work. Dust is also reduced. This creates a more efficient work area and results in better-finished parts.

Stable Results for Heat Shrink Tubes

Heat-shrink tubes must be cut with care. Length must be exact every time. A small size error can cause fitting trouble later. A smart automatic heat shrink tube cutting machine helps avoid this risk. Digital control enables users to set the length with ease. Once set, the machine repeats the same size again and again. Each cut looks clean and straight. Edges do not melt or burn. This helps wires fit well during use. The final product looks neat. It also works better in the field.

Strong Cutting for Copper Tubes

Copper tubes are strong and heavy. They need power but also control. Too much force can cause the tube to bend. Too little force can leave rough edges. A balanced system gives the best result. A strong motor keeps steady pressure. Smart feeding keeps the tube round. An automatic copper tube cutting machine handles this task with ease. Cuts stay smooth and clean. Tube shape stays perfect. This is very helpful for plumbing work. It is also useful for electric and cooling systems.

Smooth Cutting for Paper Tubes

Paper tubes are light and soft. They can break if handled roughly. A smooth and slow feed works best here. A well-designed automatic paper tube cutting machine uses soft motion. It supports the tube during the cut. Edges stay clean and flat. There is no crushing or tearing. Speed can still remain high for large orders. This helps packing and shipping work run faster. It also improves the look of finished paper tubes.

Cut-Off Systems That Save Time

A cutoff system is implemented for non-stop operation. An automatic tube cutting machine lowers the need for manual work. Workers do not need to measure by hand. This reduces human error. Staff can focus on packing or checking quality. Output rises quickly. Cost per piece drops. This makes the whole line more efficient and easier to manage.

Different Automatic Tube Cutting Machines at a Glance

| Machine Type | Best Use | Key Benefit |

| Plastic Tube Cutter | Plastic pipes | Smooth edges |

| Heat Shrink Cutter | Cable work | Exact length |

| Copper Tube Cutter | Metal tubes | No bending |

| Paper Tube Cutter | Packaging | Clean shape |

These automatic tube cutting machines are used in many industries. They support many tube sizes. They also support different materials. This makes them very flexible for modern factories.

When Laser Cutting Is the Best Choice

Laser cutting is known for high precision. There is no direct blade contact. This reduces wear and tear. A fully automatic laser tube cutting machine gives excellent edges. It works well with metal tubes. It also handles complex shapes with ease. Accuracy stays high even at fast speeds. The tool’s life lasts long. Maintenance stays low. This makes laser cutting a smart option for advanced jobs.

Smart Control and Easy Use

Modern machines are built for easy use. Touch screens guide each step. Settings are clear and straightforward. One touch can start the whole process. Memory systems save past settings. This helps repeat jobs faster. New workers can learn quickly. The machine stays stable even during long runs. Errors stay low. Productivity stays high.

Low Waste and Cost Saving

Accurate cutting helps reduce scrap. Less scrap means less waste. This directly saves money. Power use also stays low with intelligent control. Blades last longer due to clean cutting action. Service cost drops over time. This makes automatic cutting a wise long-term choice for many businesses.

Automatic Tube Cutting Machine for Precision Work

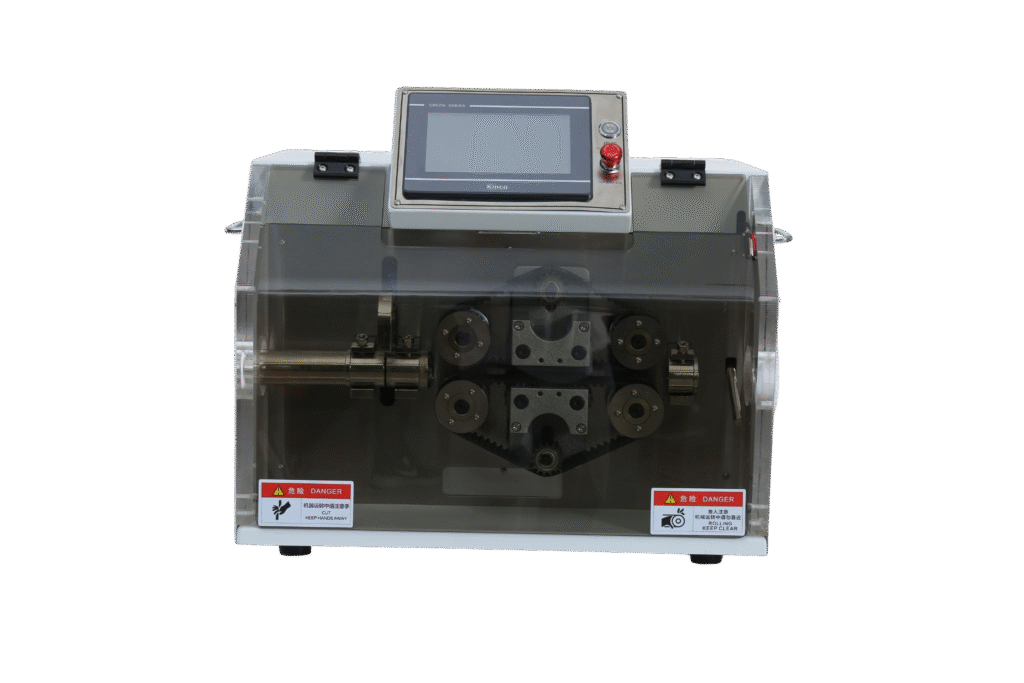

HW-8030 Computerized Wire Cutter and Stripper for Small Wires

This HW-8030 machine is compact and innovative. It is made for fine work. It cuts and strips with great care. Digital control keeps the length exact. It works well for small wires and thin tubes. Speed stays high without losing accuracy. Noise stays low during use. This makes it ideal for clean work areas.

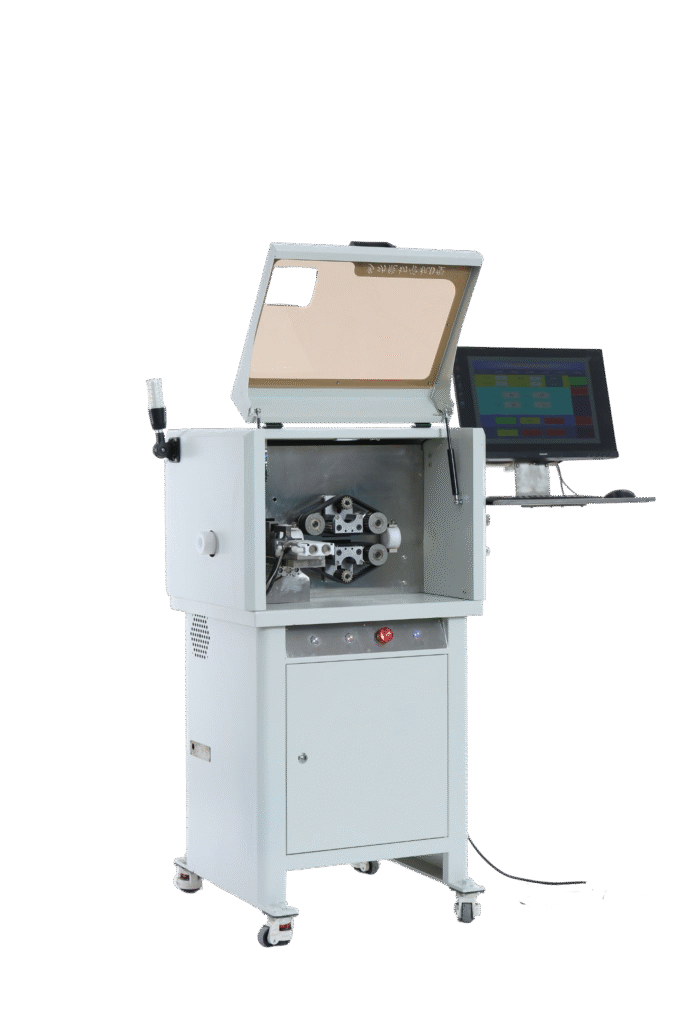

HW-8120X Precision Wire Stripping Machine with Rotary Blade

This HW-8120X model uses a rotary blade system. The blade moves smoothly during cutting. It handles strong layers with ease. Accuracy stays steady at high speed. Cuts look clean and even. This machine is a good choice for detailed tube and wire jobs.

HW-B60 Large-Diameter Corrugated Tube Cutter

This HW-B60 machine is built for large tubes. Its strong frame supports heavy work. Cutting force stays stable. The tube shape remains round. It works well in busy factory lines. It is designed for prolonged daily use without any issues.

HW-D Digital Tube Cutter for Heat Shrink and PVC Tubes

This HW-D cutter is easy to set up and operate. Digital length input saves setup time. Cuts stay smooth and clean. It works well with heat shrink and PVC tubes. Speed and accuracy stay balanced. This helps improve overall workflow.

Select VIMFUN for Exact Quality

VIMFUN is known for reliable automatic tube cutting machines. Quality control is very strict. Each unit is tested before delivery. Support teams respond fast. Spare parts are easy to get. Machines are built for long life. For full details, users can visit the official VIMFUN website. It shows machine specs, guides, and support options.

Key Benefits in Short Points

- Fast cutting speed

- Exact and repeat size

- Simple control system

- Low waste output

- Long service life

FAQs

- Are automatic tube cutting machines safe to use?

Yes. Safety guards and innovative stop systems are built in.

- Can one machine cut many tube types?

Yes. Many models work with plastic, copper, and paper tubes.

- Do these machines need skilled workers?

No. Easy screens help anyone learn fast.

- Is laser cutting better than blade cutting?

A laser is best for metal and complex designs.

- Where can I learn more about these machines?

You can find full details on the VIMFUN website.