Industrial work is often hard and tiring. You need tools that can work for a long time without stopping. Industrial wire stripping machines are designed for use in situations like those. Its design puts the highest priority on making sure it works well even in busy areas. You can easily and neatly take off the wire cover. This protects the copper inside from damage.

This is how you save material. The equipment is perfect for factories, power plants, and large work floors. It makes it less necessary to use hand tools. As a result, workers are less stressed. Another benefit is that you can keep a steady work pace. This tool makes even the hardest jobs a lot easier and safer.

Importances of Heavy Duty Machines

Heavy-duty machinery is necessary for projects of this size. A commercial wire stripping machine is known for having a lot of power and a steady speed. It easily strips cables that are thick and tough. It still works perfectly and isn’t affected by load. Because of this, the copper core stays clean and smooth. Being able to use something again and sell it is a huge benefit. These devices can work with wires of different sizes. They might have a lot of work to do every day. This makes it easier to finish tasks on time. Another good thing is that you can meet tight work deadlines. Businesses really value this dependability.

Key Benefits for Industrial Projects

There are many clear benefits to using an industrial cable stripping machine. To start with, it speeds up tasks. Things that used to take hours to do by hand now only take a few minutes. And second, it helps reduce waste. In particular, the machine takes off the lid. The copper is safe. Third, the result is always the same. This raises the standard. The machine needs stable electric power. It can run all day without stopping for breaks. This is why it works best in factories. This leads to lower labor costs in the long run. As a result, projects make more money.

Strong Design for Daily Use

When making an industrial wire stripper, durability is the most important thing. The outside is made of strong metal. This makes it less likely to break down from heat and long-term use. Also, the parts inside are strong and long-lasting. The engine makes a lot of noise, but it shifts well. This makes it possible to work for long periods of time. The machine stays stable on the ground while it works. It doesn’t move or shake. This makes workers safer. Also, it makes the cuts look neat and even. A strong design means fewer repairs and a longer life.

Automatic Control for Better Results

Modern machines use new systems. On an automatic wire stripper machine, simple, intuitive controls are standard. Users can easily change the strips’ length and depth. This is a better way to protect copper. The end product is the same for each wire. This is a very useful tool for big jobs. Touch displays make it easy to control. It’s easy for new hires to learn the ropes. To reduce mistakes, keep buttons and interfaces simple. This makes teamwork better. It makes things even better every day.

Works with Many Wire Types

When it comes to wire copper stripping machines, being able to change is very important. It may take away small wires that electronics use. It can also cut through the thick cables that power lines use. You can use both hard and soft covers. You can use it with wires that have one or more cores. This makes it useful in many different areas. It might also take the insulation off of old cables. This is good for recycling centers. It is possible to use clean copper again. This helps green and environmentally friendly work.

Electric Power for Fast Output

When you use an electric machine, the power is strong and steady. An electric wire stripping machine works at a constant speed. It stays fast even when it’s being used. There is no cut that is better than nice and neat. Electricity also makes it less necessary to do physical work. The workers shouldn’t use any force. Their main concerns might be making sure everything is set up correctly and safely. This leads to more work being done each day. It also cuts down on mistakes. Electric machines are the best choice for heavy lifting and long shifts.

Easy to Use and Maintain

Usability is very important in busy workplaces. It’s easy to use a commercial wire stripper. You don’t need advanced instruction. It is easy to learn the basics. Cleaning the equipment is very simple. It’s easy to get to the parts. So, there is less downtime. Regular maintenance keeps the equipment powerful. Simple checks can help you avoid expensive repairs. It will last longer that way. Things at work also run smoothly.

High Level Safety for Workers

Our top priority is to keep workers safe. When designing an industrial cable stripper, safety is the most important thing to think about. Use the covers and protectors that come with it to keep your hands safe. The emergency stop buttons are easy to find and reach. Because of these changes, there are fewer accidents. The tools give workers a sense of confidence. Employees trust machines more when they are safe. It also helps companies follow safety rules.

Copper Recovery and Value

One big benefit is that copper can be recovered. A copper strip machine can be used to take off insulation without cutting the metal. So, the copper stays pure. Clean copper is worth more on the market. It’s easy to sell or use it again. This helps to raise profits. Another result is less waste. Many businesses have recently made recycling a top priority. This device helps you reach those goals. It helps protect the environment.

Wire Stripping Machine & Uses

| Feature | Industrial Use | Commercial Use |

| Work Speed | High and steady for long shifts | Medium to high for daily jobs |

| Wire Types | Supports thin to thick cables | Supports many standard wires |

| Control Type | Mostly automatic systems | Manual or automatic options |

| Daily Output | Very large output | Medium output |

Top Wire Stripping Machine from VIMFUN

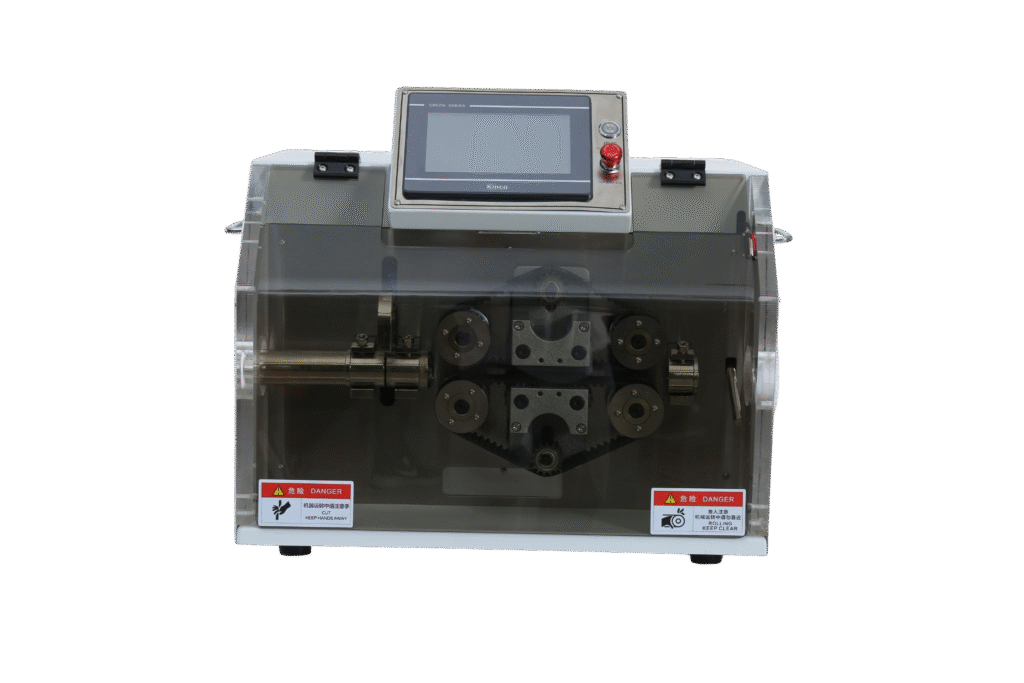

HW-8030HY Heavy-Duty Wire Stripping Machine with Touchscreen

The HW-8030HY is a powerful heavy duty copper wire stripping machine. It is built for large and continuous jobs. The touch screen is clear and easy to read. Users can quickly set size, speed, and depth. The machine consistently delivers clean and smooth results. It supports many wire sizes. The frame is strong and stable. It works well in busy factories. This machine helps teams complete work more efficiently and with higher quality.

HW-8240 High-Speed Cable Stripper for Industrial Use

The HW-8240 is a heavy duty multiple stripping machine for wire and cable. It is designed for high-speed work. It can handle bulk jobs without slowing down. The motor is strong and reliable. It keeps output steady all day. This machine is ideal for factories with heavy demand. It also protects the copper core. This helps improve overall value.

HW-B30X Automatic Conduit Cutter for Corrugated Sleeves

The HW-B30X is made for sleeve work. It is a heavy duty multiple wire and cable stripping machine for conduit tasks. It cuts corrugated sleeves clean and fast. The size stays exact every time. This reduces waste. It also lowers manual effort. This machine helps keep installations neat and professional. It is helpful in many industrial setups.

HW-C High-Precision Tube Cutting Machine for Braided Sleeves

The HW-C model focuses on accuracy. It works well with braided sleeves. It also functions as an industrial cable stripping machine for fine work. It gives smooth and clean edges. This enhances the overall appearance of the product. It is ideal for jobs that need detail and care. High precision helps maintain quality standards.

Why Choose VIMFUN

VIMFUN is known for strong and reliable machines. Their products are tested for heavy daily use. They focus on simple control and long life. Their machine range covers many tasks. From stripping to cutting, they offer complete solutions. Their support team is available to assist users when needed. Visit the official VIMFUN website to explore machines and get full details.

Common Use Areas

- Power plants and energy units

- Cable and wire factories

- Recycling and scrap centers

- Auto wiring and assembly units

- Construction and site projects

Buying Tips

When searching for a wire stripping machine for sale, always check the build quality. Look at the power rating and wire size range. Safety features are essential. Automatic control helps save time. Also, check service and spare support. This allows long-term use and peace of mind.

FAQs

What is an industrial wire stripping machine used for?

It is used to remove wire insulation fast and safely in large industrial jobs.

Can these machines handle thick cables?

Yes, an industrial cable stripper can strip thick and hard cables with ease.

Is automatic control useful?

Yes, an automatic wire stripper machine provides faster work and consistent results every time.

Does it help in copper recovery?

Yes, a copper striping machine keeps copper clean and valuable for reuse or sale.

Where can I buy trusted machines?

You can explore reliable machines on the official VIMFUN website.