As the global shift toward electrification accelerates, the demand for highly reliable, efficient, and scalable wire harness processing in the new energy and electric vehicle (EV) sectors has never been greater. From lithium battery modules to high-voltage EV wiring systems, automation plays a critical role in enabling manufacturers to meet stringent performance, safety, and production standards.

This article explores how advanced wire stripping, crimping, and harness assembly automation supports the rapidly evolving requirements of the new energy and EV industry.

Precision in High-Voltage EV Wiring

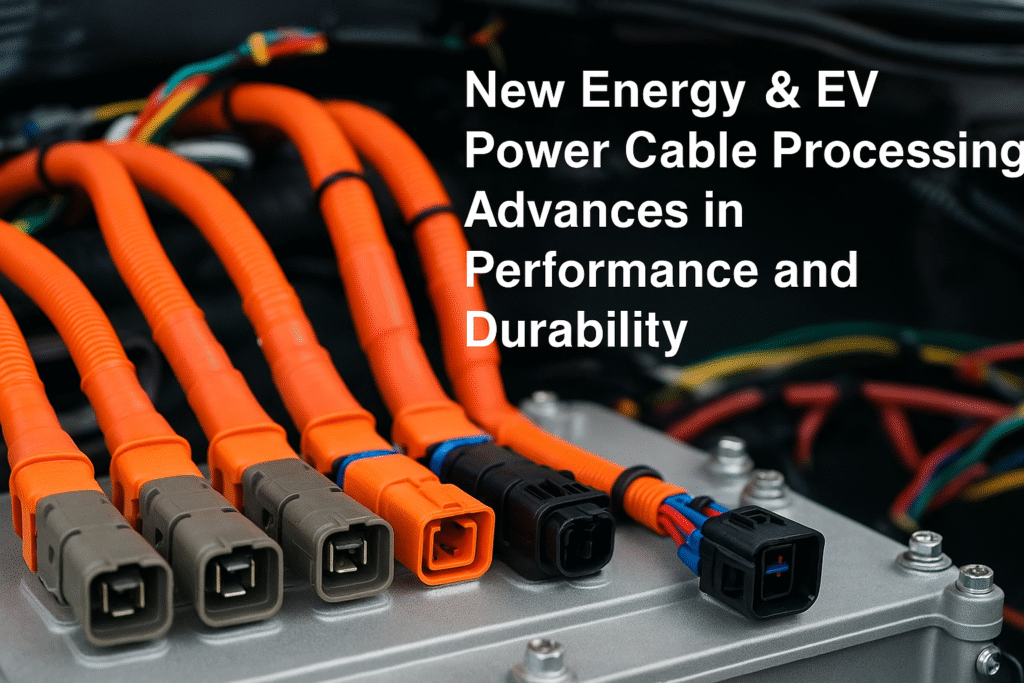

Electric vehicles rely on complex high-voltage wiring systems to power motors, battery management units, onboard chargers, and auxiliary systems. These cables must be processed with extreme precision to ensure reliable power delivery and operational safety.

Automated wire stripping and crimping machines enable consistent removal of insulation without damaging the conductor, followed by accurate terminal crimping to meet OEM quality specifications. Additionally, dual-head and multi-layer wire handling capabilities allow simultaneous processing of battery connection cables, reducing production cycle times.

👉 Click here to explore our EV high-voltage cable processing solutions.

Scalable Production for Battery Pack Integration

Lithium-ion battery packs in electric vehicles consist of hundreds or thousands of interconnected cells. These require precise wire harness assemblies for current distribution, voltage sensing, and thermal monitoring.

Wire harness automation ensures batch consistency and reduces labor variability in producing:

- Sensor and balancing wires

- Battery interconnect busbar leads

- BMS communication and control cables

High-speed wire stripping and multi-wire crimping allow scalable production without compromising quality, which is essential for high-volume EV platforms.

Enhanced Safety and Traceability

New energy systems demand exceptional electrical safety. Improper crimps or insulation removal can lead to overheating, voltage drops, or system failure. Automation mitigates these risks by:

- Standardizing every step of wire processing

- Incorporating crimp force monitoring (CFM)

- Integrating barcode or QR code tracking for each harness

Traceability and data logging features embedded in modern automation systems enable manufacturers to meet ISO/TS 16949 and IATF compliance requirements, reducing liability and improving transparency in the EV supply chain.

Flexible Adaptation to Energy Storage Systems

Beyond electric vehicles, wire harness automation is essential in stationary new energy systems such as photovoltaic (PV) arrays, energy storage systems (ESS), and inverter units.

These applications often involve varying wire gauges, insulation types, and connector interfaces. CNC-controlled stripping and crimping platforms offer programmable flexibility to adapt to diverse configurations without manual tooling changeovers.

Such flexibility enables rapid prototyping and low-volume custom harness production for hybrid or distributed energy setups.

Conclusion: Automation as a Backbone for Green Mobility

In the dynamic landscape of new energy and electric vehicles, the demand for clean, reliable, and smart wiring solutions continues to grow. Wire harness automation bridges the gap between innovation and manufacturability—delivering precision, repeatability, and speed.

As the industry pushes for faster time-to-market and sustainable mass production, automated wire processing is no longer optional—it’s a strategic necessity.