Everyday tasks may be completed quickly, neatly, and reliably with the help of a programmed electric wire cutting machine. It aids contemporary manufacturing in running more effectively while consuming less material. Consistent outcomes are guaranteed since every cut adheres to a predetermined strategy. Repeated measuring is unnecessary for workers. Doing this on the floor saves time, energy, and effort. In modern, hygienic manufacturing environments that prioritize quality, the electrical wire cutting machine is an indispensable tool.

Importances of Programmable Controls

With the programmable control, users may effortlessly adjust the cutting speed, wire length, and total piece count. The computer then does the identical thing again after saving. Sizes don’t need to be estimated or double-checked. This reduces workplace stress and errors. Because hands are kept away from blades, safety is also improved. Because of this, automatic electric wire cutting machine systems have supplanted hand equipment in numerous enterprises.

High Accuracy with Advanced Cutting Tech

Innovative cutting systems influenced by computer numerical control (CNC) wire cut electrical discharge machine designs are used by new electric wire cutting machines. Even and smooth wire ends may be achieved with the aid of these technologies. A firm wire will not break, whereas a soft wire will remain undamaged. The cutting process is stabilized by the electric wire cutting machine. Stronger goods with longer lifespans are the result of this. Further assembly procedures benefit from clean cuts as well.

Energy-Saving and Clean Operation

Modern manufacturers make energy saving a top priority. When necessary, these electric wire cutters will cut. Once the task is over, they cease. The revolutionary concept is derived from the control-intensive wire cut electric discharge machining process. Heat is reduced as a result of the job. The place is kept tidy and secure. Over time, power bills also remain reduced.

Easy Touchscreen Use for All Ages

Touchscreen panels simplify tasks for all users. The electric wire cutting machines have big, legible icons. The steps are straightforward. A new hire can pick up the ropes quickly. Deep training is unnecessary. Modern factories’ usage of computer numerical control (CNC) electric wire cutting machine systems served as inspiration for this approachable design. It is easy for people of all ages to utilize.

Strong Build for Long-Term Use

The machine remains stable all day long thanks to its strong metal structure. Fast cutting keeps vibration to a minimum. This ensures precision for long durations. The inspiration for the design came from the robust wire cut electrical discharge machining equipment. The parts last a long time. Machine downtime and repair expenses are reduced as a result.

Flexible Cutting for Many Materials

These electric wire cutters are versatile and can accurately cut through many different kinds of wire. Coated wire, soft cable, copper, and aluminum are all acceptable. Additionally, certain versions can cut sleeves and tubes. The principles of material control-intensive wire cut electro discharge machining have inspired this broad utilization. Multitasking is made easy with only one machine.

Safety Features for Daily Work

Priority one is safety. Covers, protections, and automatic stop systems are all part of these electric wire cutters. The machine promptly stops if an issue occurs. Tools and hands are protected in this way. To keep people vigilant, clear warning indications are necessary. It is one of the top options for safe factories that is inspired by wire cut electric discharge machining and has these qualities.

Recommended Machines for Smart Production

HW-8030HY Heavy-Duty Wire Stripping Machine with Touchscreen

Heavy lifting and extended periods of use are ideal for the HW-8030HY. It balances delicately when stripping and cutting wires. The touchscreen allows for easy and fast setup. Users have the option to store their settings in case they need to do things again. Because of this, big factories are able to run more smoothly and with less human mistake. Luminous assembly lines complement it well.

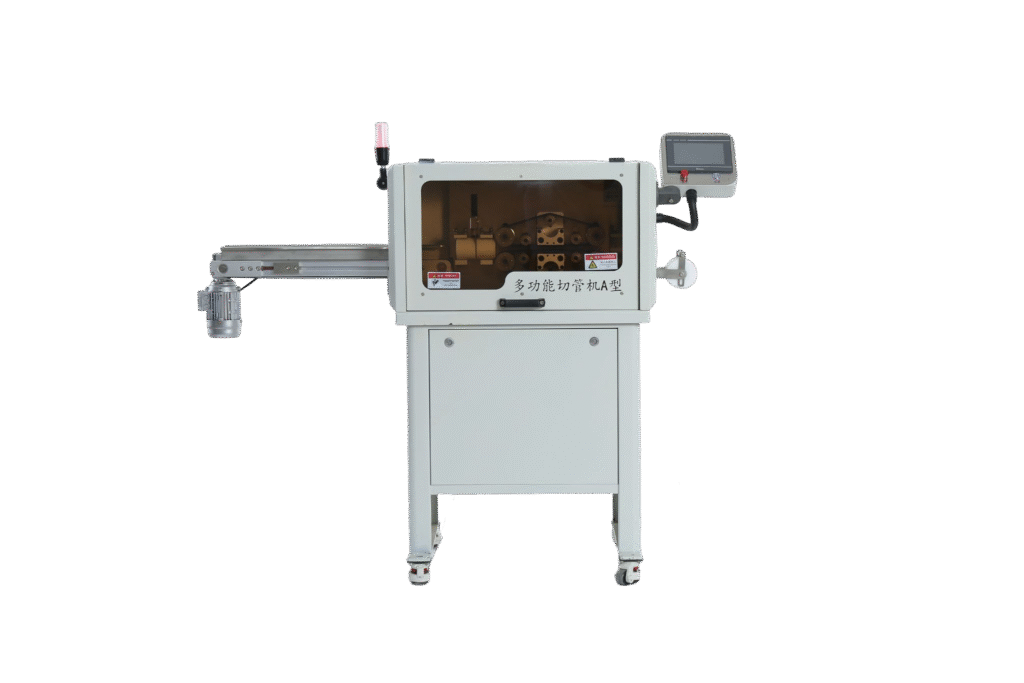

HW-A Multi-functional Tube Cutting Machine

Multiple tube types can be supported by a single unit in the HW-A variant. It effortlessly slices through both flexible and stiff tubes. Reduced footprint means more room on the floor. It works well for both big and small workshops. This machine can multitask. Workflow on a daily basis is enhanced.

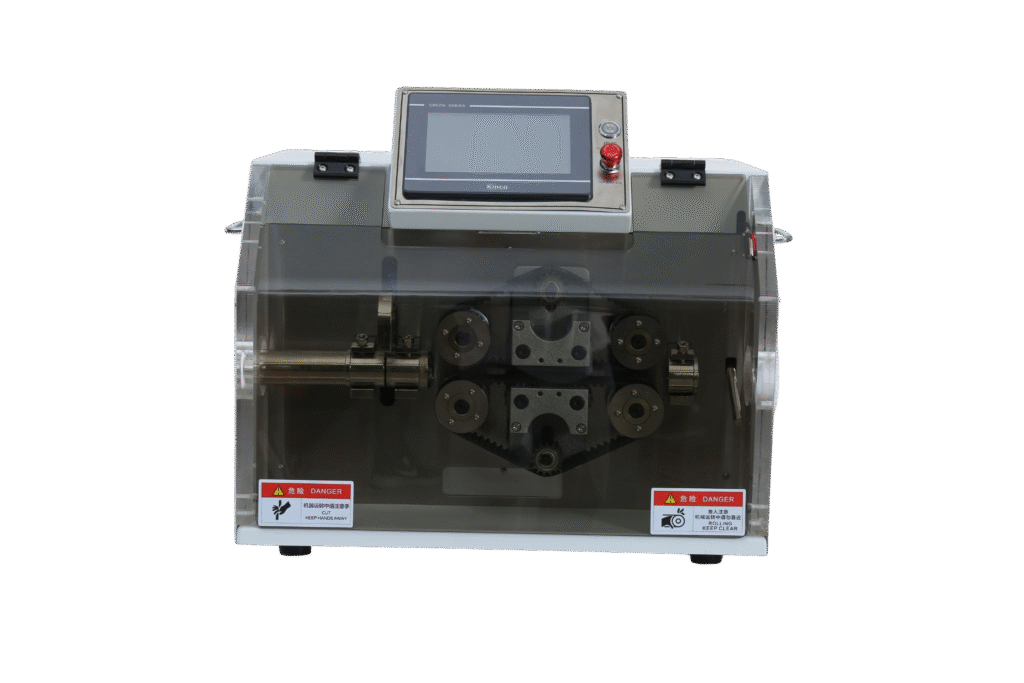

HW-B30X Automatic Conduit Cutter for Corrugated Sleeves

Consistent power and rapid processing are hallmarks of the HW-B30X. It neatly cuts corrugated sleeves. The automated feeding mechanism reduces manual labor. All of the pieces appear identical. Large bulk projects are a breeze with it. Efficiency remains high throughout the day.

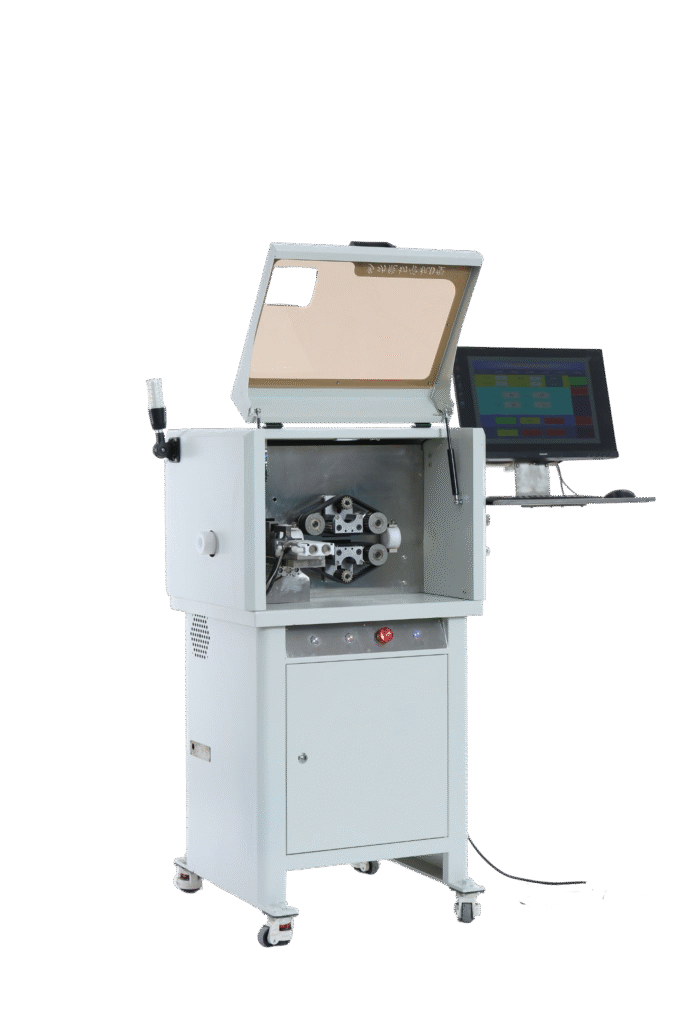

HW-D Digital Tube Cutter for Heat Shrink and PVC Tubes

For fragile and tiny tubes, the HW-D model is ideal. All lengths are precisely measured under digital control. It is compatible with PVC and heat shrink tubes. It is safe to say that the machine operates quietly. For smaller manufacturing facilities and research labs, it works well.

Benefits at a Glance

- Fast and smooth cutting every time

- Easy control with transparent screens

- Very low waste and error

- Strong body for long service life

- Safe design for daily use

Key Applications

- Cable assembly workshops

- Electrical panel production

- Tube and sleeve cutting jobs

- Smart and automatic factories

| Feature | Programmable Machine | Manual Tool |

| Speed | Very fast | Slow |

| Accuracy | Very high | Low |

| Safety | Advanced | Basic |

| Waste | Very low | High |

| Ease of use | Very easy | Hard |

VIMFUN provides trusted electric wire cutting machines for innovative industry needs. The website shows full product details with clear images. Support teams respond quickly and provide practical assistance. Many global factories rely on VIMFUN tools daily. Visiting the VIMFUN website enables buyers to discover robust, modern, and reliable wire cutting solutions.

FAQs

- What is a programmable electric wire cutting machine?

It is an intelligent machine that cuts wires using saved programs. Each cut stays the same. This helps save time and material.

- Is it better than manual cutting?

Yes. It works faster and more safely. It also gives better accuracy and less waste.

- Can beginners use these machines?

Yes. Simple screens and clear buttons make them easy for all ages to use.

- Do these machines support automation?

Yes. Many models are connected to fully automatic production lines.

- Where can I find reliable machines?

You can explore trusted options on the VIMFUN website, which is known for its quality and service.