In today’s fast-moving manufacturing world, efficiency and precision matter more than ever. Corrugated tubes are used in many industries, from electronics to automotive wiring, to protect cables and wires. Chopping these tubes fast and right is a must. That’s where automatic corrugated tube cutting machines shine. They’re made to save you time, cut down on waste, and make sure every tube is a perfect cut. No matter if you’re in a small shop or a big factory, a smart tube cutter can boost how much you make and keep your customers smiling.

Working Principle of Tube Cutting Machines

Automatic corrugated tube cutter runs on a plan that’s both easy and smart. The tube slides into the machine, sometimes by hand, sometimes automatically. A motor then rolls the tube to where the cutting happens. Sharp blades and careful measuring do the job, slicing the tube to the length you need. Some machines even use sensors and computer smarts to make sure each cut is just right. This whole thing happens again and again, really fast, so you get lots of tubes done in little time. The size can change on its own for different tubes, which is super handy.

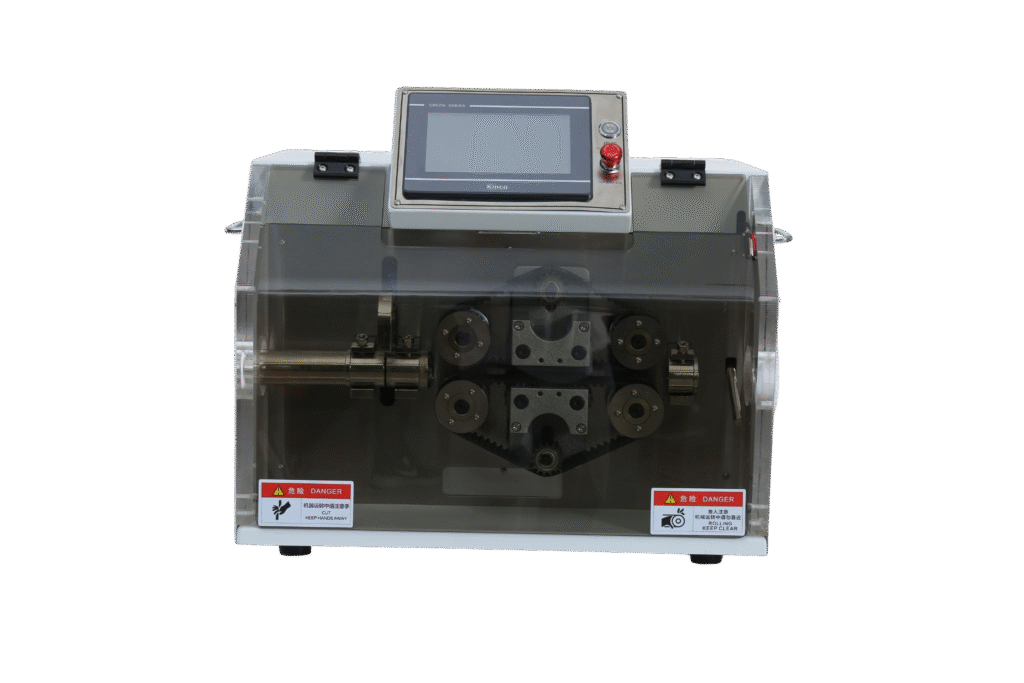

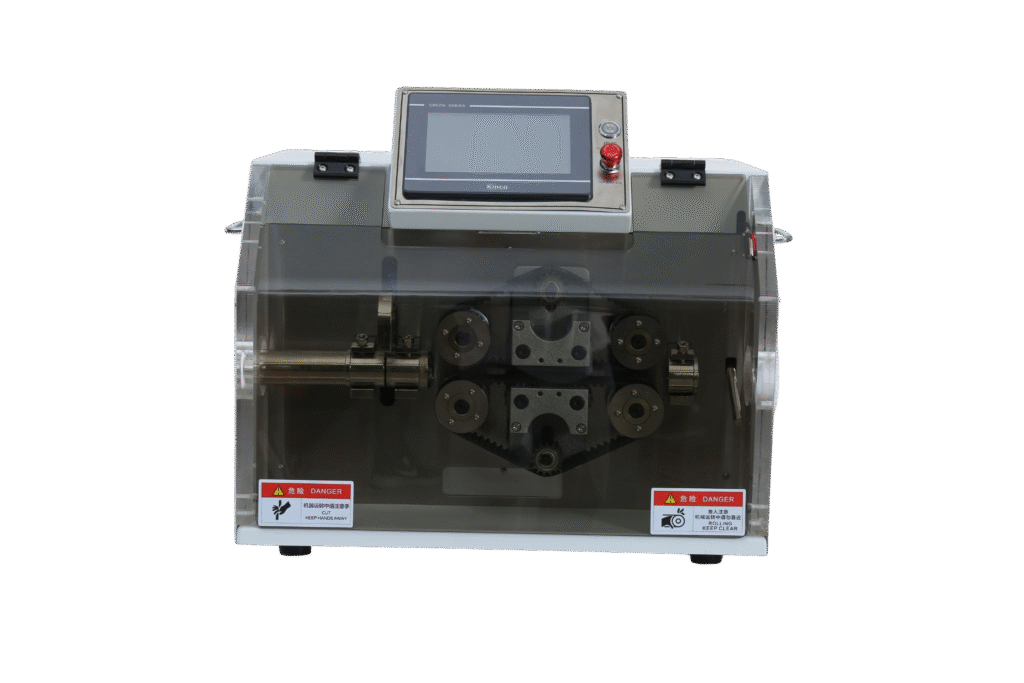

Advanced Corrugated Tube Cutting Machine (HW-B30)

The HW-B30 Tube Cutting Machine is built to cut tubes fast and with great accuracy.

It can handle PVC and PE corrugated tubes as big as 30 mm around. It’s awesome for wire work and automated setups. Its cutting system is all about accuracy, so each tube gets a clean, even cut. This means less waste and more time saved.

This plastic corrugated pipe cutting machine can cut tubes from 1–30 mm, and there are choices for tubes up to 45 mm. It’s accurate to within ±1%, so you know each cut will be right. The HW-B30 can chop up to 60 pieces per minute, which can help factories make a lot of product.

With its electric PLC-controlled drive, the machine makes cuts that are smooth and without rough edges. This makes for better tubes that are ready to assemble and less need to clean them up by hand.

VIMFUN makes this machine, and they’ve been in the wire processing biz for over 15 years. Their machines are famous for being accurate and reliable, and they offer help all over the globe.

Features of Our Smart Corrugated Tube Cutters

Our corrugated tube cutting machines are loaded with stuff to make making things easy and sure. They have settings you can change, so you can set the tube length and cut speed quickly. The blades are top-notch, so you always get smooth cuts. Lots of machines also feed tubes in automatically, which means less work for you. The control panel is simple to use, so anyone can run it without problems. All these things add up to save you time and make more stuff.

Precision Cutting for Consistent Tube Quality

Being spot-on matters a lot when cutting tubes. If a tube is too long or short, it can cause issues when putting things together or wiring them up. Automatic corrugated tube cutting machines are made to cut each tube the same way every time. Sensors and fancy controls make sure every cut matches the length needed. This means fewer mistakes and less wasted material. With spot-on cuts, your product quality goes up, and your team spends less time fixing errors.

Energy-Efficient Design for Lower Operating Costs

Modern tube cutting machines are designed not to use a lot of energy. They have motors that don’t waste power and smart controls to keep energy use low. This means cheaper electric bills and a smaller effect on the environment for your factory. Saving energy also means less heat and wear on the machine. This keeps it running well for longer without breaking down. By picking a machine that uses energy smartly, you’re looking out for your money and the planet.

Applications Across Industries and Materials

Corrugated tubes are used everywhere, and so are these cutting machines. They can cut tubes no matter if they are made from plastic, rubber, PVC, or other stuff. Cars use them for wire setups and protection. Electronics use them to guard cables in devices and machines. Even things around the house use them to keep wires neat and safe. A cutting machine that can handle different tubes and sizes is handy in many different areas.

Smooth Operation with Minimal Downtime

When a factory has to stop, it can cost a lot. Our corrugated tube cutting machines are made to run smoothly and keep problems to a minimum. Automatic feeding systems and careful cutting mean you don’t have to change things all the time. Maintaining it is easy, and most of the parts are constructed to last a long time. There are plenty of changes, and don’t even shut down the whole line to swap out a blade if it gets dull. That puts your factory into operation without a hitch, saving time and money.

Built-In Safety and Protection Features

In any factory, the number one priority is always keeping safe. The automatic corrugated tube cutting machine is equipped with safe devices to protect people from danger. Sensors can detect if hands are too close and immediately shut down the machine. Emergency stop buttons are readily accessible, and covers keep dust and bits away from moving parts. And lots of machines won’t allow the motor to be pushed into overload, preventing damage. With these in place, your team will be able to work without fear, and this can reduce the likelihood of accidents.

Easy Integration with Existing Production Lines

A precision tube cutting system should fit right in with what you already have. Our machines are made to hook up easily with other gear, like wire processing or assembly lines. They can work with automatic feeders, crimping machines, or testing stations. This means less handling by hand and keeps the line moving along. When things work together, you get the most out of your investment and make things even more efficient.

How to Choose a Perfect Tube Cutting Machine?

The right CNC tube cutting machine for you will depend on what you’re making. “Think about the tubes that you use, what they are made out of and how big they are. Then see how quick the machine is, how accurate and if people can rely on it.”

Also, consider energy and safety if you want to protect your team and keep costs down. It doesn’t hurt if the controls are straightforward and if it’s easy to keep clean! Ultimately, choose a company that you trust with automation experience. When you pay attention to these things, you can choose a machine that saves time while doing things better and growing with your business.

Trusted Company for Industrial Tube Cutting Solution

One of the most well-known names for a high-speed corrugated pipe cutter is VIMFUN. They are all about making and selling gear for every step of wire automation. Their stuff covers everything from stripping and cutting to crimping, taping, and testing. With years of doing this and a focus on being new and improved, VIMFUN makes reliable machines. These help factories make more, make fewer mistakes, and keep product quality consistent all over the world.

To Sum It Up

They’re key to making things today. They mix speed, accuracy, and safety to make things more efficient. By picking flexible tube cutting equipment with great features that save energy and run smoothly, factories can save time, produce less waste, and boost quality. When they fit with your other gear, and you have reliable help from a trusted company like VIMFUN, these machines are a smart buy. No matter if you’re cutting plastic, PVC, or rubber tubes, an automatic cutter is the key to making things fast and well.

Quick Questions

What’s a corrugated tube cutting machine?

It’s a machine that automatically cuts tubes to just the right length.

Can it cut different tubes?

Yes, it can work with plastic, rubber, PVC, and the like.

Does it save energy?

Yes, machines today use less power and save you cash.

Will it fit with what I already have?

Yes, smoothly with other wires and assembly gear.

Who makes the best machines?

VIMFUN is a name you can trust with lots of experience in wire automation.