Custom Case

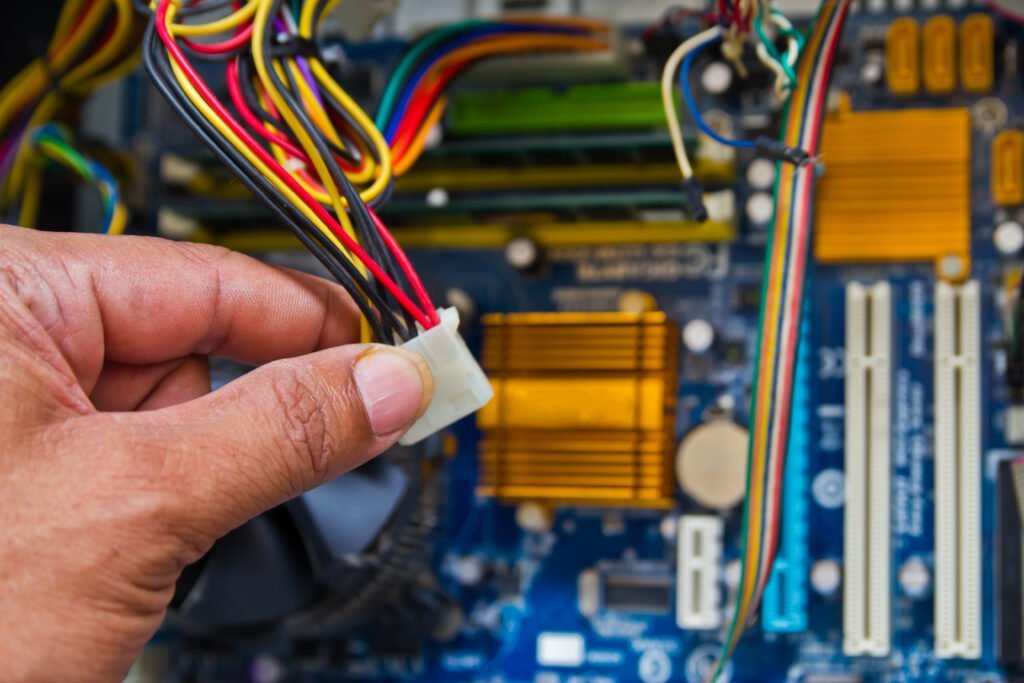

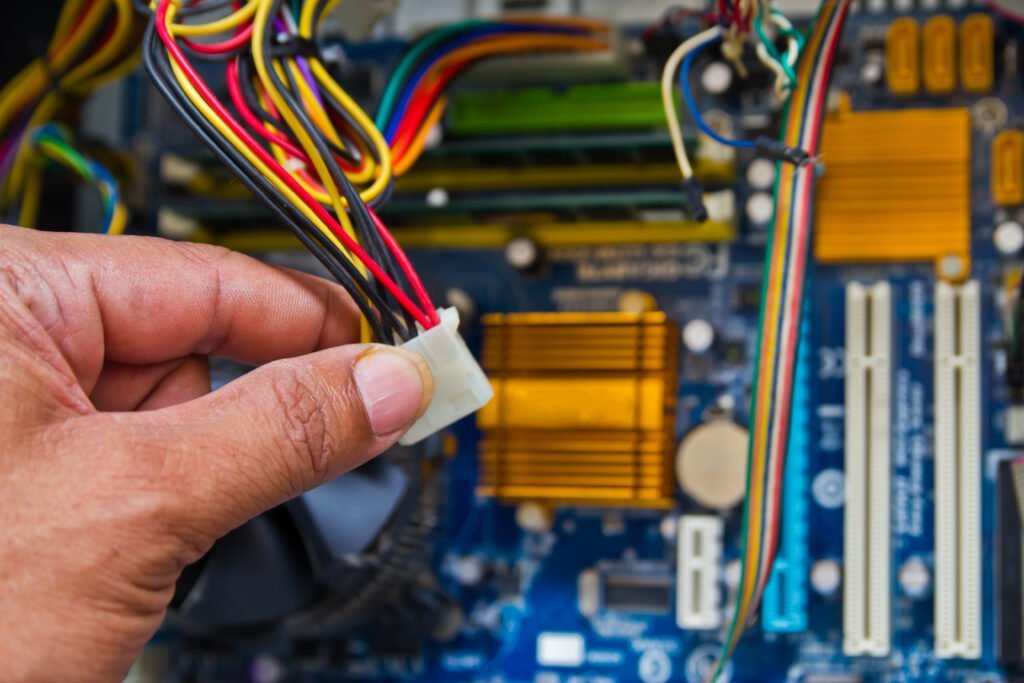

In 2020, a leading 3C electronics manufacturer approached VIMFUN to design and build a fully customized wiring harness processing solution. The client required a high-efficiency, high-precision system to handle the complex wiring needs of smartphones, tablets, and other compact electronic devices, covering fine wire cutting, stripping, crimping, and automated assembly.

After detailed discussions and on-site evaluations, our engineering team developed a tailored production line integrating fully automatic micro-wire stripping machines, precision crimping stations for micro-connectors, and intelligent quality inspection systems. The solution ensured stable processing speed, consistent crimping quality, and maximum space efficiency for miniaturized device assemblies.

Within weeks of installation, the new production line significantly improved output capacity while maintaining strict quality standards, helping the client accelerate product launches in the highly competitive 3C electronics market.

After in-depth discussions and on-site assessments, our engineering team developed a tailored production line integrating fully automatic wire stripping machines, double-end crimping stations, and intelligent quality inspection systems. The solution ensured stable production speed, consistent crimping quality, and minimized manual intervention.

Within weeks of installation, the production line significantly boosted output capacity while maintaining strict quality standards, helping the client accelerate their EV manufacturing process.

Manufacturing · Customized 3C Electronics Wire Harness Solutions

From concept to completion, we provide tailored wire harness automation solutions for 3C electronics, including smartphones, tablets, laptops, and smart home devices. Our engineering team works closely with clients to turn complex wiring requirements into efficient, high-precision production systems. Whether you need a full production line or specialized equipment optimization, we ensure precision, reliability, and consistency at every stage.

Requirement Confirmation

Design & Validation

Technical Agreement

Manufacturing & Delivery

Delivery & Installation

Once the customized automation equipment has completed production and testing, we conduct multiple full-process trial runs before shipment to ensure stable coordination across all stations and that the cycle time meets production requirements.

The equipment is packaged with shockproof and moisture-proof protection, and professional logistics is arranged for delivery to the customer’s site.